Monday Accidents & Lessons Learned: Multiple Train Car Derailment Causes Massive Passenger Disruption

Just after 2:20 pm on Monday, August 14, 2017, a freight train carrying containers derailed in Cambridgeshire, England. The rear 12 wagons of the diesel locomotive derailed when the train crossed over a set of points near the Ely North junction. The train was traveling at 41 mph at the time of the derailment. It ran derailed for approximately 385 yards, causing significant damage to the infrastructure, which had to be replaced. No one was injured in the incident.

Passenger services were disrupted for days, while a crane was brought in by Network Rail to move the heavy derailed wagons prior to repairs.

Why it happened

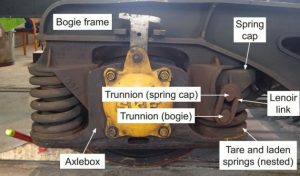

The first wagon to derail was an FEA-A wagon fitted with Y33 bogies. (A “bogie” is an undercarriage with four or six wheels pivoted beneath the end of a railroad car.) The derailment occurred because the damping on the bogies of this wagon was ineffective. A report by the Rail Accident Investigation Branch (RAIB) summed up this finding in its determination that the first wagon to leave the track did so because the system to stop it bouncing on the rails was ineffective.

The damping had become ineffective because the damping components, which had been on the wagon since it was built in 2003, had been managed to incorrect maintenance limits. The limits did not account for future wear in the period before the next maintenance checkup and were not compatible with the configuration of the damping system. Further, the maintenance interventions, since a general repair in 2010 (the last time when these components had been measured), were ineffective in identifying the worn state of the components.

It is also likely that the company responsible for the maintenance of the wagon did not appropriately validate the general repair maintenance specification used in 2010 to confirm that it would ensure continued safe operation up to the next planned general repair due in 2017.

The fleet of wagons has since gone through general repair and all of the damping components have been replaced.

Recommendations

The RAIB report recommended to the company responsible for the maintenance of the wagons to review its maintenance documentation to ensure that the bogies on its freight wagons remain adequately damped at all times.

In addition, the report identified three learning points: “The first reminds those responsible for updating maintenance instructions that repair limits quoted in guidelines or by manufacturers should not be used as maintenance limits as this provides no future operational life. The second learning point reminds entities in charge of maintenance that they should have a validated system of maintenance that ensures that the vehicles for which they are in charge remain safe for operation. The final learning point reminds maintainers of this type of bogie that some of them are fitted with an inspection window to allow the damping system components to be visually examined.”

The report underscored that the freight train’s components had not been properly maintained for 14 years.

Circumstances can crop up anywhere at any time if proper and safe sequence and procedures are not planned and followed. We encourage you to learn and use the TapRooT® System to find and fix problems. Attend one of our courses. We offer a basic 2-Day Course and an advanced 5-Day Course. You may also contact us about having a course at your site.