787’s Covered Static Ports Highlight Importance of Clear, Unambiguous Procedures

A Boeing 787 used for a freight flight flew from Melbourne to Los Angeles with tape covering four static ports, a new ATSB (Australian Transport Safety Bureau) investigation report details.

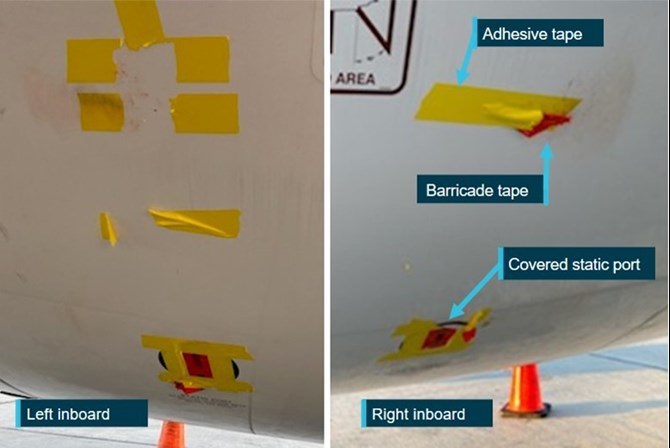

After the Qantas 787-9 aircraft, registered VH-ZNJ, landed in Los Angeles on the morning of September 22, 2021, a Qantas engineer found tape covering the four static ports on the aircraft’s engine fan cowls.

Static ports provide important air pressure data to aircraft systems. Boeing recommends they be covered, to avoid contamination, when the aircraft is parked for periods up to 7 days, and Qantas incorporated this instruction into its “normal” parking procedure.

The ATSB investigation details that on the day before the incident flight, an engineer undertook the parking procedure on the aircraft, which included covering the engine cowl static ports with “remove before flight” barricade streamer tape.

“Later that day, another engineer was tasked to conduct the “restore” procedure to return the aircraft to flight status,” ATSB Director Transport Safety Stuart Macleod explained.

“The tape on the engine fan cowls was not removed by that engineer, as per the manufacturer’s procedures, and this wasn’t identified by flight crew or dispatch during pre-departure checks.”

VH-ZNJ subsequently took off with the tape still on its engine fan cowl static ports.

“While the flight was uneventful, the covered ports meant redundancy for the engine electronic control system was reduced,” Mr. Macleod noted.

The ATSB found that while the job instruction card (JIC) developed by Qantas for parking a 787 did link to Boeing’s recommended procedures, the JIC for restoring it back to service did not.

“This was a missed opportunity to assist engineers to readily access the current procedures and determine which ports were covered, and also allowed for different interpretations of which ports could be covered,” Mr. Macleod said.

“When performing safety‑critical tasks like aircraft maintenance, it is very important that procedures are clear and unambiguous to avoid misinterpretation and error such as occurred in this incident.”

In an interview, the flight crew’s second officer, who conducted an exterior inspection of VH-ZNJ before the flight, reported they were aware of the fan cowl ports, but not that they could be covered by tape.

The second officer also reported they were somewhat distracted during the inspection, as they had found a pitot tube cover on the ground, and were trying to hand it off to an engineering staff member at that time.

“The second officer also believed Qantas engineering had conducted a pre-flight inspection prior to the flight crew arriving at the aircraft,” Mr. Macleod added.

Following the occurrence, Qantas distributed memos to engineering, and flight and ramp crew, highlighting the location of the fan cowl static ports and that they may be covered.

In addition, the airline amended its “park” and “restore” engineering instructions to both reference Boeing’s procedures.

The investigation report also notes the meter-long tail of the “remove before flight” tape covering the static ports was stuck down, to prevent it being torn from the fuselage in strong winds, as per Boeing’s recommended procedure.

“This likely reduced the visibility of it covering the fan cowl static port covers,” Mr. Macleod said.

“Targeted inspection of locations and components, rather than relying on streamers, which can detach, can help to identify when these covers or devices have not been removed.”

Key points:

- Boeing 787 being used for freight operations flew from Melbourne to Los Angeles with tape covering its engine cowl fan static ports;

- While the flight was uneventful, the covered ports meant redundancy for the engine electronic control system was reduced;

- Job instruction card for restoring a 787 to service did not link to Boeing’s recommended procedures;

- Qantas has amended its engineering instructions to properly reference Boeing’s recommended procedures.

Safety message

When performing safety‑critical tasks like aircraft maintenance, it is very important that procedures are clear and unambiguous to avoid misinterpretation and error such as occurred in this incident.

“Remove before flight” streamers are a reminder to remove covers, or lockout devices, prior to flight. Failure to remove these devices and covers can prevent the functionality of certain aircraft systems. In certain circumstances, the streamers may be fixed to the aircraft and not hang freely, which can reduce their visibility. Targeted inspection of locations and components, rather than relying on streamers, which can detach, can help to identify when these covers or devices have not been removed.

Source: ATSB, “787’s covered fan cowl static ports highlights importance of clear and unambiguous procedures.”

Read the ATSB report: AO-2021-040 Aircraft flight preparation occurrence involving Boeing 787-9, VH‑ZNJ Melbourne Airport, Victoria on 22 September 2021.

Circumstances can crop up anywhere at any time if proper and safe sequence and procedures are not planned and followed. We encourage you to learn and use the TapRooT® System to find and fix problems.

TapRooT® has a team of investigators and instructors with years of extensive training ready to offer assistance worldwide. We also offer ongoing support to our clients through free newsletters and root cause tip videos, the root cause analysis blog, and our annual Global TapRooT® Summit.

Register for one of our courses. We offer a basic 2-day course and an advanced 5-day course. Contact us or call 865.539.2139 about having a course at your site or for further root cause analysis opportunities. We’re here to find solutions for you.

Contact us to discuss training your employees on-site. You may also call us at 865.539.2139 to speak to an instructor, schedule an executive briefing, or book on-site training for your team.