The Reality of High-Reliability Organizations

High-Reliability Organization Misconceptions

For the past decade, I’ve seen people write about their ground-breaking research about high-reliability organizations. It often makes me chuckle because I’ve worked in a high-reliability organization and what the researchers “learn” isn’t always what is really going on.

First, let me say that my high-reliability organization experience was in Admiral Rickover’s Nuclear Navy. Seven years and two ships – the USS Arkansas and the USS Long Beach – both nuclear-powered cruisers. I had close friends on submarines and nuclear-powered carriers. To learn more about the Nuke Navy’s record and Rickover’s philosophy, read the series of articles HERE.

High-Reliability Organizations: Research vs Reality

So what is the difference between research and reality? Here are some of the ideas to consider…

1. Real high-reliability organizations vs fake high-reliability organizations.

Rickover’s Nuclear Navy was the original high-performance organization. In my experience, there isn’t anything that comes close. I’ve seen research that described carrier flight deck operations as a high-reliability organization. But from the accidents and injuries I’ve seen or heard about, I just don’t think they meet the standard.

That brings up a question. What is the standard?

I think the answer is ZERO. Rickover’s Nuclear Navy was (and still is even after he is gone for almost forty years) an organization that achieves an amazing record of ZERO reactor safety-related accidents. There were no fatalities, no major releases of radioactive material, and no core-melt accidents. And this record was set during Rickover’s leadership when the Navy was running hundreds of reactors at sea every year. Today that’s a record of sixty years of continuous operation of many nuclear reactors without a major reactor-related accident.

If you are in the process industry, think of this as all the US refineries having no fires or explosions or significant environmental releases for 60 years.

For carrier aviation to qualify as a high-reliability organization, they would have to have zero flight deck-related fatalities, explosions, or aviation-related crashes on all the US carriers for years. As far as I know, they don’t achieve this record for a single year (usually not a single deployment).

Therefore, if you are going to learn from a high-reliability organization, make sure it is a real high-reliability organization.

2. High-Reliability Organizations aren’t good at everything.

Rickover’s Nuclear Navy record for reactor safety was amazing. However, submarine or nuclear surface ship industrial safety was pretty average. Thus, the same excellence emphasis was not applied to everything.

Let’s use a sports example. If you are a great athlete, you have the chance to excel at a sport. But you probably can’t be good at every sport. The world’s greatest basketball player may not be able to switch over and become the world’s greatest baseball player … or golfer. They might be better than average, but they probably won’t be great.

Why? Because being great requires focus. If your focus becomes too broad, you lose your focus and your performance slips. Thus, you can talk about high-reliability organizations like they are great at everything, but they probably aren’t. They probably focus their attention on one aspect of performance to become great.

3. The high COST for exceptional excellence.

You can ask the Nuke Navy sailors about the cost of excellence:

- 12 to 18-hour days, seven days a week

- failed marriages

- burnout

Recruiting the exceptional sailors required to meet the highest standards wasn’t easy (and still isn’t easy). There are large financial bonuses to recruit and keep Nuke Navy sailors in the Nuke Navy.

This is a significant chunk of change to keep the best because the average sailor just isn’t good enough for Rickover’s Nuclear Navy.

4. Weak Signals

Research about high-reliability organizations describes detecting “weak signals” that indicated problems. Let me put this straight. If you are in a high-reliability organization, those signals aren’t weak. They scream out at you.

The problem is that non-high-reliability organizations wear a double set of hearing protection. Many don’t hear or see the signals until dead bodies pile up at their feet.

There is no secret to hearing the signals. If you know what makes your systems highly reliable, then you make sure that these important factors are looked after, maintained, and nurtured. The Rickover article linked above lays out these factors for the Nuclear Navy (and they are the same factors that apply to process safety).

Here’s an example…

If the budget is cut so that you start getting a maintenance backlog, that isn’t a weak signal. Management high and low should be hearing the signal (there is a maintenance backlog).

If the budget is cut, so safety significant maintenance is not getting done, the system is screaming at you. (This should be monitored and discussed in weekly management meetings.)

If you are having precursor incidents because of deferred maintenance, the top management (the COO/CEO) should know about it and should be demanding changes.

Thus weak signals aren’t weak if you are a high-reliability organization.

And if you think they are weak signals – you aren’t in a high-reliability organization.

Real Life vs Research

That’s a start. I’ll stop here and not belabor the point.

Living high-reliability and

researching high-reliability

are two different experiences.

If I were going to get advice about becoming a high-reliability organization (quite a challenge if you aren’t one), I would talk to someone who lived in a high-reliability organization and who also has worked at a non-high-reliability organization. Or, better yet, I would hire that person to help lead the effort. I would not become part of someone’s university research detached from the experience of living in the organization.

If you are thinking about becoming a high-reliability organization, be ready for difficulties and major change. Talking about high reliability is much easier than living a high-reliability life.

Learn More About High-Reliability Organizations

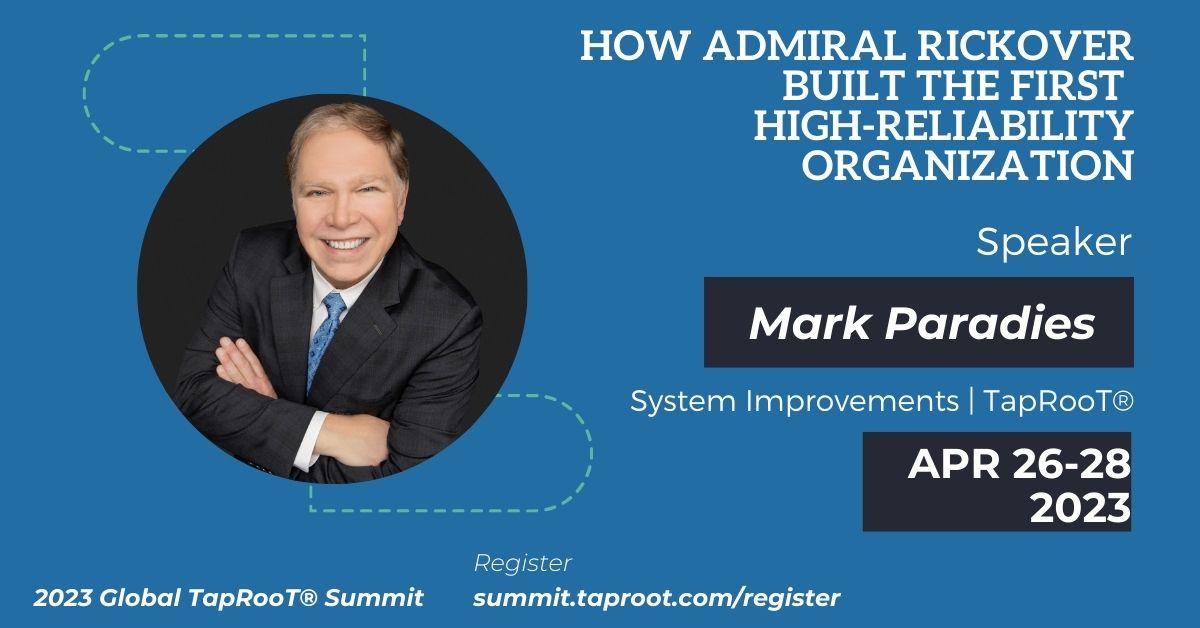

To hear more about how Rickover developed the first high-reliability organization, attend Mark Paradies’ talk at the 2023 Global TapRooT® Summit titled:

How Admiral Rickover Built the First High-Reliability Organization

Mark will highlight Rickover’s standards and provide you the opportunity to discuss how they may be applied to your organization.

To register for Mark’s session in the Building a Superior Improvement Program Track at the Summit, CLICK HERE.

To download the Summit Brochure, click on the image below.