How To Lie With Statistics

Great Book

One of my favorite “business” books is an old one titled: How to Lie With Statistics by Darrel Huff. Written in 1954 (before I was born), it is just as applicable today (maybe more so) as it was the day it was written.

An Example of Lying with Statistics

Whenever I think about the book, I also think about my first job after I left the Navy. I was in a performance improvement group, and I went to a presentation about incident statistics by the manager in charge of their incident database. This was an annual presentation to senior executives, and the theme of his talk was that human error was the biggest cause of incidents, and we needed to improve human performance. That’s what his statistics said.

Since this was my focus, I thought …

“Great! We will be solving one of the biggest problems around!”

We dived into creating a human performance program, but, by the next year, we hadn’t accomplished much. We had made some starts, met major resistance, and had plans for more efforts, but we really hadn’t made much impact. I knew that his presentation would show that problems persisted.

Instead, I was surprised. He didn’t mention human performance or human error. He had a new theme. The main problem for improvement was equipment reliability. That’s what the statistics said.

I thought …

“How can this be?”

We had not made significant progress solving the human error causes. How could the statistics change without changes to the system?

So, I got access to the data and started comparing previous data.

What did I find?

- BAD DATA. The measurement system was corrupt. There wasn’t a good way to ensure that incidents were being investigated thoroughly and the results could be manipulated. Thus, the person interpreting the data could make it say whatever he or she wanted it to say.

- BAD GRAPHS. There wasn’t a standard set of graphs that management looked at year after year. A new set of graphs were presented at each annual review. No one wanted to admit that progress was slow (or non-existent) … so, they created a new crisis (area for improvement) each year and just declared victory over the old problem because it wasn’t the biggest problem anymore (even though it really had NOT disappeared).

- BAD QUESTIONS. Management didn’t ask the right questions. For example, management should have asked …

“What happened to the human error problems you told us about last year?”

“Show us the graphs that demonstrate the improvement.”

“What were the programs that caused this improvement?”

They should have known about the lack of progress over the years and been familiar with the incidents that kept happening over and over again. They should have seen that very little progress had been made in the prior six years.

But they didn’t.

They just waited for the next year’s presentation and were glad that so much progress was being made. I think they actually wanted to be lied to.

What Did Leaders Need?

Leaders needed a good measurement system and graphs that helped them improve performance. That’s why we created the course,

Measurement, Trending, and Predictive Analytics:

How to Best Use Data to Improve Work

Kevin McManus, Chief Excellence Officer of Great Systems LLC, is the creator of this course. His experience includes:

- Virtual coaching and content to help people use proven best practices to enhance and optimize their daily work systems.

- Over forty years of work experience in roles such as Industrial Engineer, Training Manager, Production Manager, Plant Manager, and Director of Quality.

- Teaching TapRooT® Root Cause Analysis in over 425 courses.

Kevin holds an undergraduate degree in Industrial Engineering and an MBA. He served as a national Malcolm Baldrige Performance Excellence Award Examiner for twenty years, including a three-year term on the national Judge’s Panel. Kevin has authored the monthly performance improvement column for Industrial and Systems Engineer magazine for over 20 years, is an Institute of Industrial and Systems Engineering Fellow, and has been a member of IISE for over forty years.

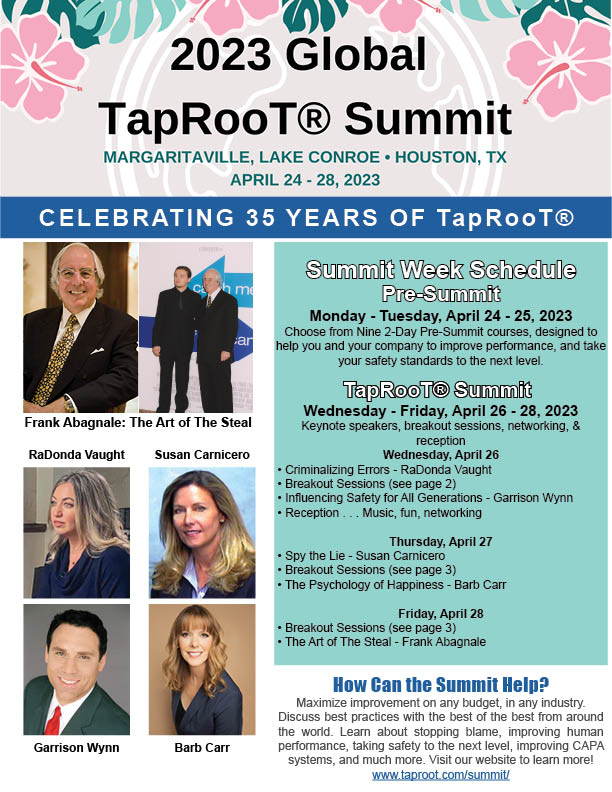

Would you like to know how to properly use your company’s incident and daily workday data to improve performance? Then you should attend this course being held on April 24-25, prior to the 2023 Global TapRooT® Summit, near Houston, TX.

For more Summit information, click on the brochure below…

Don’t miss out. Register for both the course and the Summit TODAY and SAVE $300 OFF the course fee.