Missed Opportunities

It Didn’t Have to Happen!

MISSED OPPORTUNITY EXAMPLE 1: An anesthesia machine cuts off oxygen to a patient causing extensive brain damage. The investigation team found a mechanical defect that was undetectable without complex testing. They also found that the sentinel event (major hospital error) almost happened before but wasn’t investigated because, in the prior incident, no harm occurred.

MISSED OPPORTUNITY EXAMPLE 2: The baggage door on a 747 opens after takeoff, tearing off part of the plane. Four people are swept out of the hole to their death. The investigation uncovers prior, less catastrophic, accidents of a similar nature and a history of problems with the door on this particular aircraft. The corrective actions for the previous incidents hadn’t been implemented.

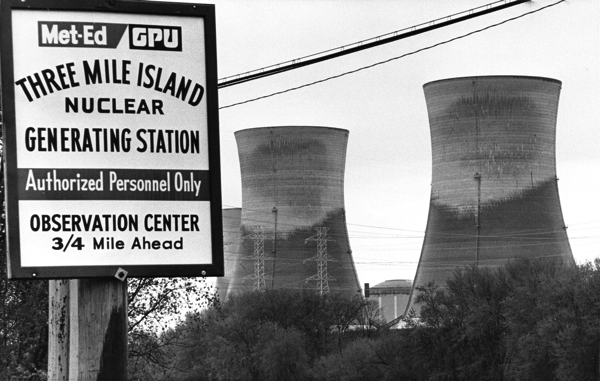

MISSED OPPORTUNITY EXAMPLE 3: A plant upset occurs due to corrective maintenance. A relief lifts but fails to shut when pressure decreases. Operators, initially preoccupied with other alarms, misdiagnose the problem and shut off critical safety equipment. The “impossible” accident – a core meltdown – happens at Three Mile Island. The investigation uncovers similar precursor incidents and a history of relief valve failures at TMI and other similar nuclear plants. But the incidents didn’t get a thorough root cause analysis and adequate corrective actions.

These missed opportunity example accidents didn’t have to happen. They are typical of hundreds of “missed opportunities” that happen every year. The cost?

- Lives lost.

- Suffering for survivors and surviving loved ones.

- Millions – no billions – of Dollars (Yen, Euros, and Pounds).

We could prevent ALL of these major accidents. Why don’t we? Don’t we know that:

An ounce of prevention is worth a pound of cure?

Benjamin Franklin

Maybe it is:

- Intellectual laziness?

- Shortsightedness?

- Just plain bad management?

- A bad system to identify problems?

- Bad investigation techniques?

- Something else?

What would it take to start learning and stop missing opportunities?

STEP 1: Management Understanding

Your management – from the CEO down – must understand the problem … People and machines are variable (you might call them unreliable) BY NATURE.

Our job is to reduce variability and make systems reliable and safe.

In the long run, a safe, reliable system will always outperform an unreliable, unsafe system.

Therefore, improving reliability and safety provides your company with a competitive advantage.

The competitive advantage IS NOT FREE. It requires upfront effort and investment in root cause analysis and improvements. It requires persistent attention to detail.

Thus, attaining reliability and safety is the challenge.

We have a course that can help management understand their role in performance improvement and root cause analysis. Get more information HERE.

STEP 2: Get a Performance Improvement & Root Cause Analysis System That Works

Although Ben Franklin’s advice seems simple, consistently identifying the right “ounce of prevention” can be complex.

How dangerous is it to reason from insufficient data.

Sherlock Holmes

Improving safety and reliability requires a systematic approach and the use of sophisticated performance improvement techniques. You need a good performance monitoring system.

A good performance monitoring system includes:

- self-reporting of near misses

- reporting and instigation of accidents and precursor incidents

- audits, observations, and self-assessments

- advanced root cause analysis (TapRooT®) that meets all the root cause analysis fundamental requirements

- advanced statistical analysis of trends

- understanding of how to fix human performance problems

- training for those who make the system work

Is putting together this kind of a system a tall order? You bet. But it is worth it.

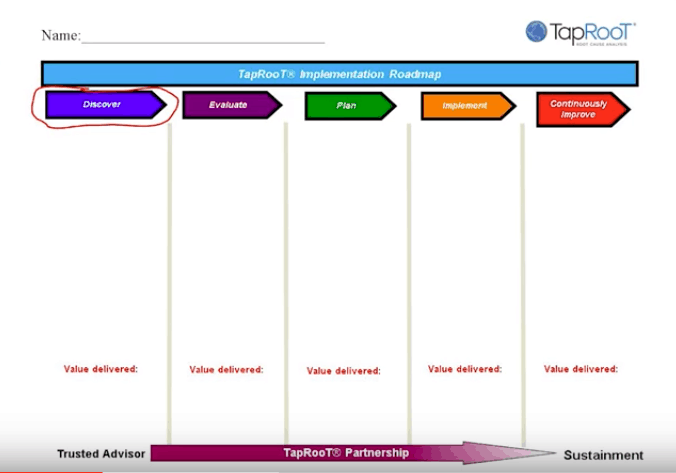

If you need help putting this type of system together, we have the experience to help you, and we can provide the training that people need. Call us at 865-539-2139 or drop us a note. We will help you develop a Roadmap to Success.

Here is a video about how we helped people develop a Roadmap to Success at the 2019 TapRooT® Summit.

CLICK HERE for the dates and locations of our public TapRooT® Root Cause Analysis Courses.

STEP 3: Use the System & Fix Problems

Get your facts first.

Then you can distort them as much as you please.

Mark Twain

Preventing accidents is NOT a quick fix. Something you can do once and forget. Management needs to stay involved. You must be CONSISTENTLY PERSISTENT.

Find and fix the root causes of accidents, precursor incidents, near-misses, and audit findings.

The first measure of the system’s effectiveness IS NOT a reduced accident rate (although this will come along quickly enough). The first measure of success is an increased rate of finding and implementing effective corrective actions.

Management needs to demand that people properly use the system to investigate problems, find their root causes, identify effective fixes, and get them implemented. If management doesn’t demand this, it won’t happen.

STEP 4: Never Stop Improving

If you aren’t better today than you were yesterday, you are falling behind. As my boss once said:

If you’re not peddling, you are going downhill.

Captain William J. Rodriguez, United Staes Navy

Never stop looking for areas that need improvement. This should include improving your improvement system!

We can help. How? Several ways…

- Call us at 865-539-2139, and we can discuss your plans to improve. We will help you develop your Roadmap to Success. The call is FREE, and we may be able to suggest ways to make your plan even better.

- We can conduct an independent audit of your root cause analysis implementation, trending, and performance improvement systems. Although this isn’t free, we guarantee it will be worth the time and money. Just drop us a note to get things started.

- Attend the Global TapRooT® Summit. Each year we design the Summit to help people learn to solve the toughest problems that your industry is facing. You will network with some of the world’s most knowledgeable performance improvement experts and peers who have faced the same types of problems that you face and found best practices to solve their problems. Then we help people develop a custom Roadmap to Success to take back to work and make improvement happen.

Don’t wait for the next “missed opportunity.” Do something to make improvement happen before a major accident takes place.

Save lives – save money – save jobs – improve quality and reliability – that’s what TapRooT® is all about.

(A Best Of Article from the Root Cause Network™ Newsletter – Updated and Reprinted from the April 1994 Root Cause Network™ Newsletter, Copyright © 1994. Reprinted by permission.)