Monday Accident & Lessons Learned: OPG Safety Alert #259 – FATALITY DURING CONFINED SPACE ENTRY

FATALITY DURING CONFINED SPACE ENTRY

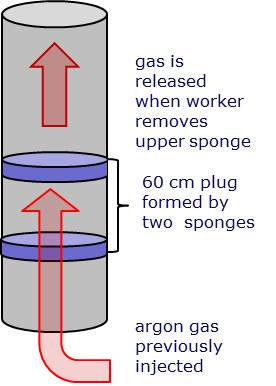

- Two cylindrical foam sponge pads had been inserted in a riser guide tube to form a plug. Argon gas had been pumped into the 60 cm space between the two sponges as shielding gas for welding on the exterior of the riser guide tube.

- After completion of the welding, a worker descended into the riser guide tube by rope access to remove the upper sponge. While inside, communication with the worker ceased.

- A confined space attendant entered the riser guide tube to investigate. Finding his colleague unconscious, he called for rescue and then he too lost consciousness.

- On being brought to the surface, the first worker received CPR; was taken to hospital; but died of suspected cardio-respiratory failure after 2 hours of descent into the space. The co-worker recovered.

What Went Wrong?

- Exposure to an oxygen-deficient atmosphere: The rope access team members (victim and co-worker) were unaware of the asphyxiation risk from the argon gas shielding.

- Gas test: There was no gas test done immediately prior to the confined space entry. The act of removing the upper foam sponge itself could have released (additional) argon, so any prior test would not be meaningful.

- Gas detectors: Portable gas detectors were carried, but inside a canvas bag. The co-worker did not hear any audible alarm from the gas detector when he descended into the space.

- Evacuation time: It took 20 minutes to bring the victim to the deck after communication failed.

Corrective Actions and Recommendations

Lessons:

- As a first step: assess whether the nature of the work absolutely justifies personnel entering the confined space.

- Before confined space entry:

– identify and communicate the risks to personnel carrying out the work

– define requirements, roles and responsibilities to control, monitor and supervise the work

– check gas presence; understand how the work itself may change the atmospheric conditions

– ensure adequate ventilation, lighting, means of communication and escape - Ensure step by step work permits are issued and displayed for each work phase, together with specific job safety analyses

- During confined space entry:

– station a trained confined space attendant at the entrance to the space at all times

– ensure that communication and rescue equipment and resources are readily available

– carry and use portable/personal gas detectors throughout the activity

ACTION

Review your yard confined space entry practice, keeping in mind the lessons learned from this incident.

safety alert number: 259

OGP Safety Alerts http://info.ogp.org.uk/safety/

Disclaimer

Whilst every effort has been made to ensure the accuracy of the information contained in this publication, neither the OGP nor any of its members past present or future warrants its accuracy or will, regardless of its or their negligence, assume liability for any foreseeable or unforeseeable use made thereof, which liability is hereby excluded. Consequently, such use is at the recipient’s own risk on the basis that any use by the recipient constitutes agreement to the terms of this disclaimer. The recipient is obliged to inform any subsequent recipient of such terms.This document may provide guidance supplemental to the requirements of local legislation. Nothing herein, however, is intended to replace, amend, supersede or otherwise depart from such requirements. In the event of any conflict or contradiction between the provisions of this document and local legislation, applicable laws shall prevail.