Robinson R22 Loses Engine Power, Conducts Forced Landing

A Robinson R22 helicopter pilot had to conduct a forced landing after a sudden loss of engine power due to damage to an engine cylinder intake valve, an Australian Transport Safety Bureau (ATSB) investigation has determined.

On January 11, 2022, R22 VH-VHE was being used to conduct mustering operations southwest of Mitchell, in Queensland’s central south.

“During the second mustering flight of the day, the pilot of the R22 reported hearing a pop and a crack, and experiencing significant uncommanded yaw, and abnormal vibration, resulting in a forced landing,” ATSB Director Transport Safety Stuart Macleod said.

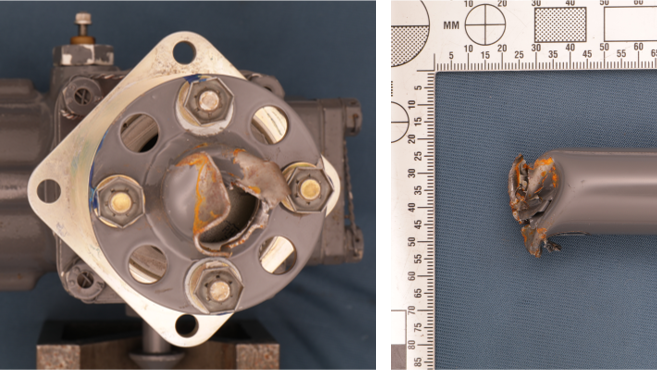

Examination of the R22 engine by a maintenance organization, and further examination at the ATSB’s technical facilities in Canberra, confirmed that damage to the engine’s number-four cylinder intake valve had allowed the fuel and air mixture, and exhaust gases, into the air induction system.

“This resulted in the degraded engine performance and forced landing of the R22 helicopter,” Mr. Macleod said.

Notably, prior to the incident, neither the pilot nor the maintenance organisation observed any indications of the progressing damage to the intake valve, including during a successful compression test 17.6 flight hours prior to the incident.

“While not required, a borescope inspection may increase the likelihood of detecting valve damage that can lead to degraded engine performance,” Mr Macleod noted.

VH-VHE’s engine had been overhauled in August 2021 – six months prior to the incident – and the pilot stated that the engine seemed underpowered following the overhaul.

“In piston engine helicopters, unexpected yaw and reduced engine performance may be symptomatic of developing engine intake valve damage,” Mr. Macleod said.

“If this condition remains unattended, it can lead to an increased risk of induction backfire events and significant loss of engine power.”

Mr. Macleod added there is an opportunity to improve understanding of engine issues with better quality data.

“Maintenance organizations are therefore encouraged to follow the Civil Aviation Safety Authority recommendation for borescope inspections of valves and report any defects, or nil-defect findings.”

The ATSB’s report also notes that, for reasons that could not be determined, the tail rotor drive shaft fractured as a result of torsional overstress during the incident.

In addition, an unapproved modification was present on the leading edge of the tail rotor blades, although this probably had no influence on the occurrence.

Key points:

- R22 pilot conducted forced landing after sudden loss of engine power during low-level mustering operations

- Examination found damage to the engine’s number-four cylinder intake valve led to reduced engine performance

- Occurrence illustrates the potential seriousness of unexpected yaw and reduced engine performance during flight

Read the final report: Engine power loss and forced landing involving Robinson R22 Beta, VH-VHE 130 km south-west of Mitchell, Queensland on 11 January 2022.

Founded in 1988, the TapRooT® Root Cause Analysis System solves hurdles every investigator faces

TapRooT® Root Cause Analysis Training System takes an investigator beyond his or her knowledge to think outside the box. Backed with extensive research in human performance, incident investigation, and root cause analysis, TapRooT® is a global leader in improved investigation effectiveness and productivity, stopping finger-pointing and blame, improving equipment reliability, and fixing operating problems.

TapRooT® Root Cause Analysis Training courses are taught all over the world

System Improvements, the creator of the TapRooT® System, has a team of investigators and instructors with years of extensive training ready to offer assistance worldwide.

If you are interested in learning how to stop repeat incidents, find a 2-Day or 5-Day course; or view the complete selection of TapRooT® courses. We are available to train you and your staff on-site at your workplace; Contact us to discuss your needs. You may also call us at 865.539.2139 to discuss any questions you may have.