Root Cause Analysis Tip: Analyze Things That Go Right … The After-Action Review

Some claim that root cause analysis is only a reactive tool … something to use AFTER something bad happens.

A much better idea is to use root cause analysis proactively to stop bad things before they happen.

One way to use root cause analysis proactively is to analyze success.

Even when things don’t go wrong, do a root cause analysis after-action review to find out why things went right. Once you understand what causes success, you can repeat success and avoid failure.

To do an after-action review root cause analysis, start by drawing a SnapCharT® of the real way the job was done. Analyze the risks taken and why things worked. You may be able to find ways to make the process even better or to eliminate risks that weren’t necessary. This might make you even more successful next time.

Also, look for things that made the process work and make sure they aren’t lost. Success is a habit and you need to make sure that good practices aren’t forgotten.

Some of the worst stories of failure I’ve heard were people who thought they were saving time, effort, or money but were actually removing the steps in the process that made success happen. When things later failed, it was because they had “lost” good practices to cost cutting and efficiency efforts.

Once you have a good SnapCharT®, look for the opposite of root causes using the Root Cause Tree®.

What is the opposite of a root cause? First think about this definition of a root cause:

Root Cause

The absence of a best practice or the failure to apply knowledge that would have prevented the problem.

(From The TapRooT® Book Copyright © 2008. Used by Permission.)

The Root Cause Tree® helps you look for missing best practices or missing opportunities to apply knowledge. Therefore, you can use the Root Cause Tree® to spot where you were using good practices and knowledge to avoid (eliminate) Causal Factors. The absence of these Causal Factors helped you be successful (not have an incident).

Once again, we want to reinforce the good practices and make sure they aren’t eliminated by mistake.

For example, if the mechanic used a checklist, reinforce that that was a good practice that should be used again. Don’t let the mechanic get the idea that “now that I’ve done it once successfully, I don’t need a checklist any more.”

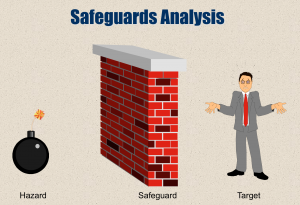

One additional technique that can be helpful in recognizing why things went right is Safeguards Analysis.

When we teach Safeguards Analysis, we usually use safety examples because these are the easiest way to understand the concept of a safeguard.

But the same concept can be applied to quality problems, maintenance issues, or operations excellence. The idea is to look for the safeguards that were in place to keep problems from occurring.

You may find that even if you were successful, you may have had some safeguards fail but an accident, quality problem, maintenance failure, or operating problem didn’t occur because another redundant safeguard worked.

For example, a mechanic working on a pump might have opened the wrong valve and contaminated a batch of chemicals being processed in a nearby unit, but didn’t because he asked an operator to second check what he was about to do. He had made a mistake following a procedure (a failed safeguard) but asking the operator to second check his work (an additional safeguard) kept things from going wrong.

In this case we can reinforce the safeguard that worked (the second checker), but need to do a root cause analysis on the safeguard that failed (maintenance error that was caught by the second check). The root cause analysis portion of this after-action review is just like the root cause analysis of any other incident (SnapCharT® and Root Cause Tree®). The only difference is that the Causal Factor was not allowed to become an incident because another safeguard worked.

One last note. Analyzing things that go right is perhaps the most important part of an improvement program for companies that have excellent performance.

Why? Because when your performance is excellent, there are usually redundant safeguards that keep performance at this high level. Analyzing what goes right allows management to see if one of those redundant safeguards is failing without waiting for additional safeguards to fail (causing a real accident).

Using TapRooT® Root Cause Analysis to analyze why things go right is a best practice that the best should be using!

If you would like to learn more about applying TapRooT® Root Cause analysis either reactively or proactively, consider attending a 5-Day TapRooT® Advanced Root Cause Analysis Team Leader Course. CLICK HERE for more information.