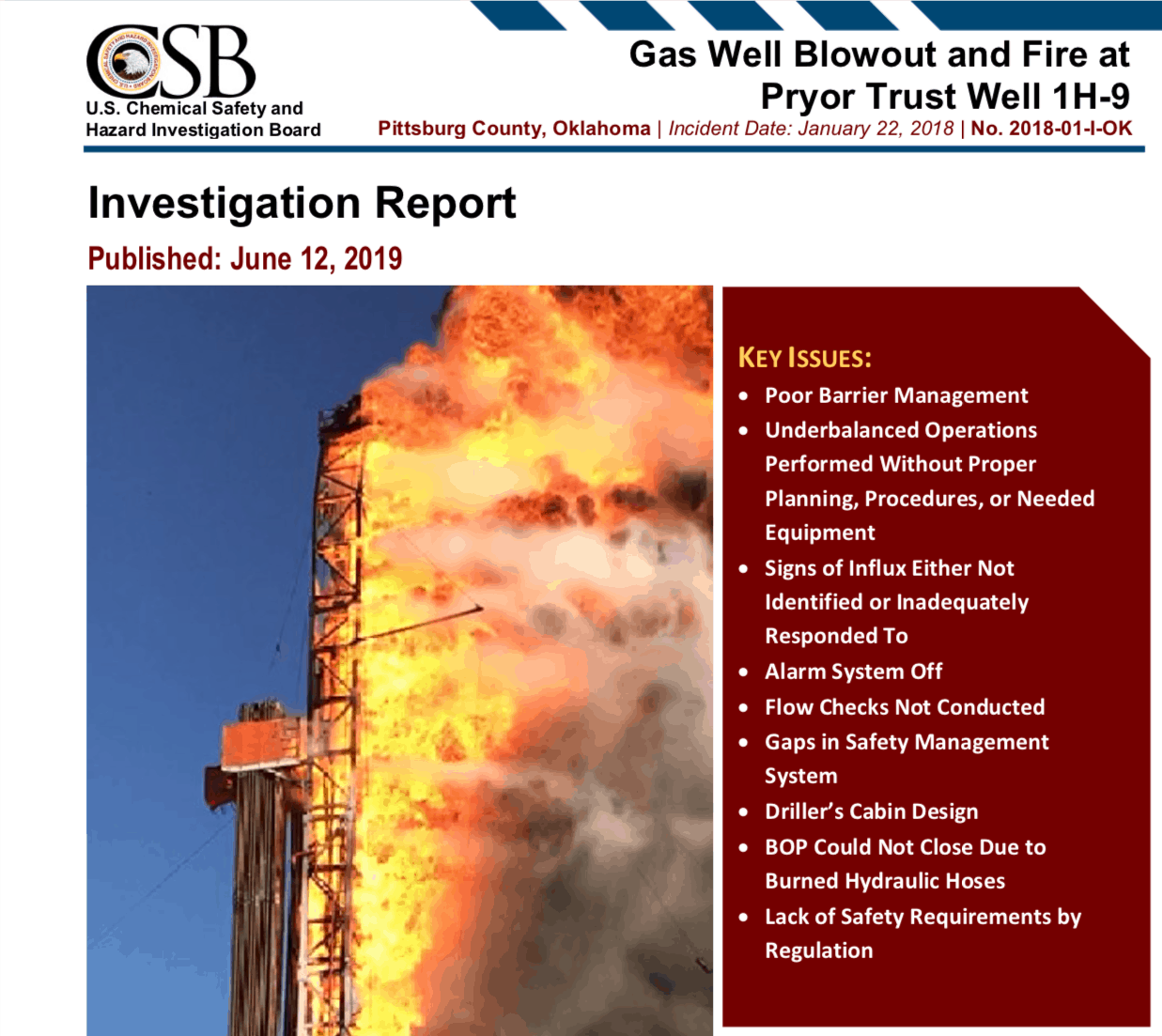

CSB Final Report into Fatal Gas Well Blowout in Oklahoma

CSB Recommends New Regulations & Industry Guidance After Accident

Here is a link to the Chemical Safety Board’s final report on a Gas Well Blowout in Oklahoma. All the pictures below are from the report (and there are many more in the report).

Here is a link to the CSB press release about the blowout investigation.

Accident Causal Factors

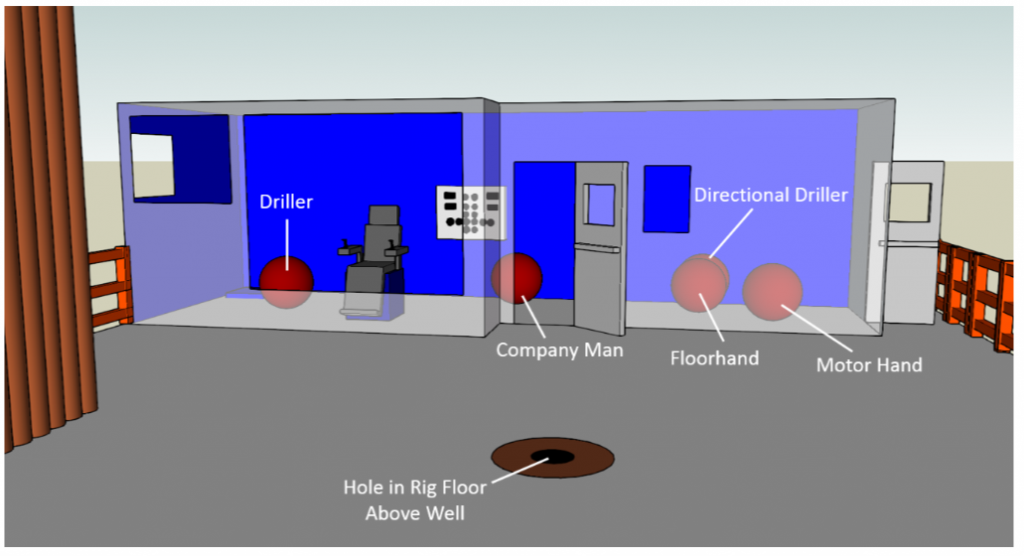

The accident was fairly simple. Over a 14 hour period the gas well drilling operation:

- Was frequently underbalanced allowing gas to enter the well from the formation.

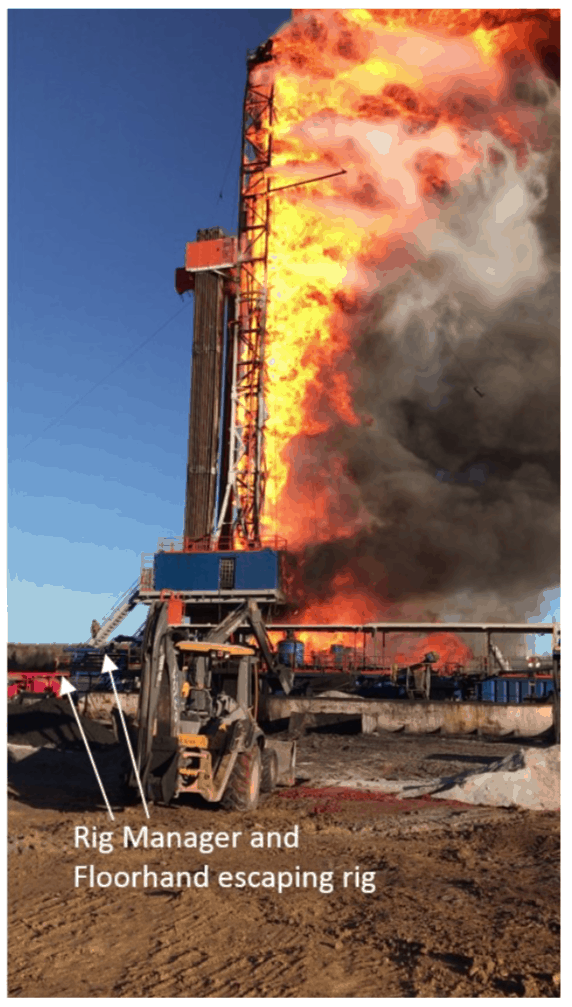

- The people involved did not detect the gas leaking into the well or took no action to secure the well until after a fire had erupted and disabled the blowout preventer.

In addition:

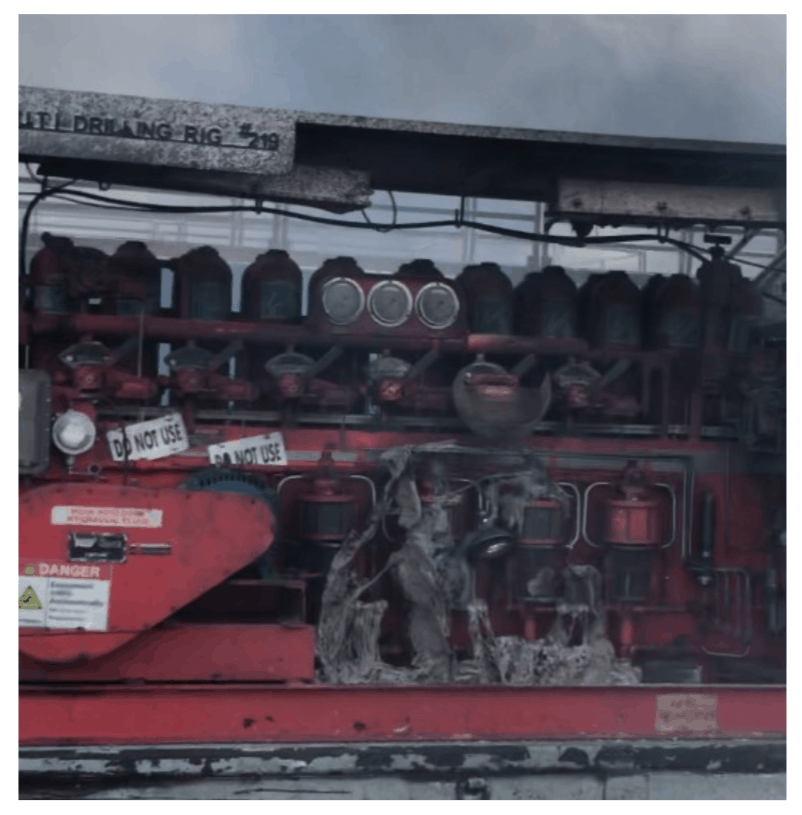

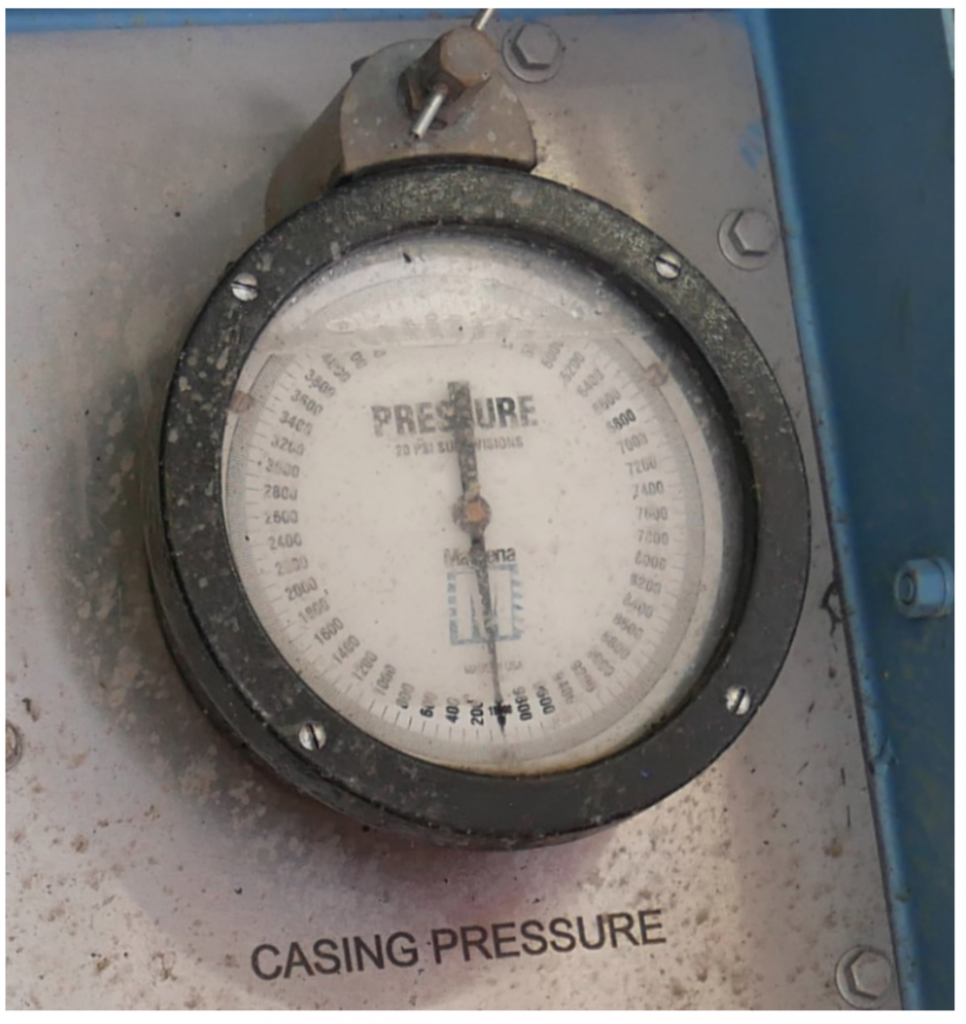

- The blowout preventer failed to work because of fire damage (probably melted hydraulic hoses and controls).

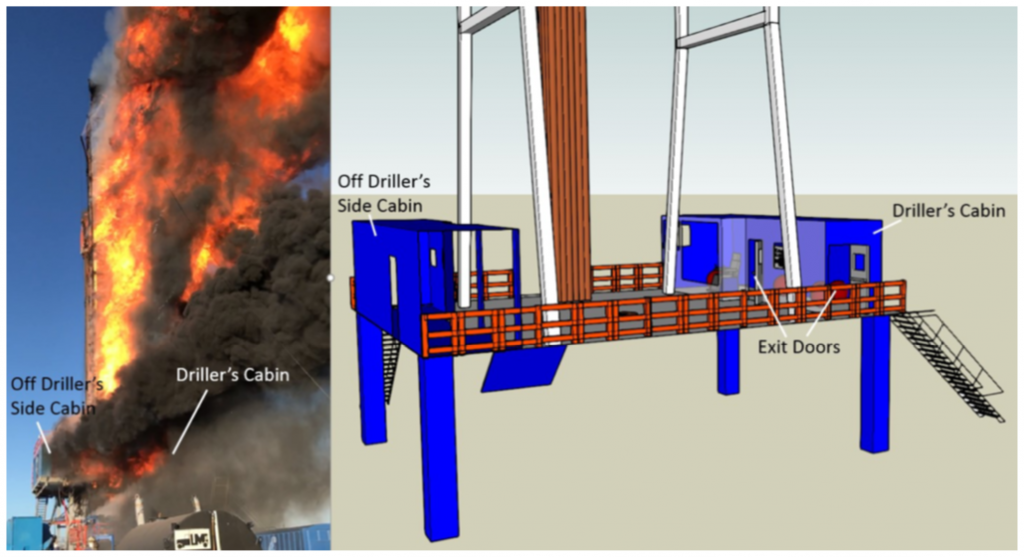

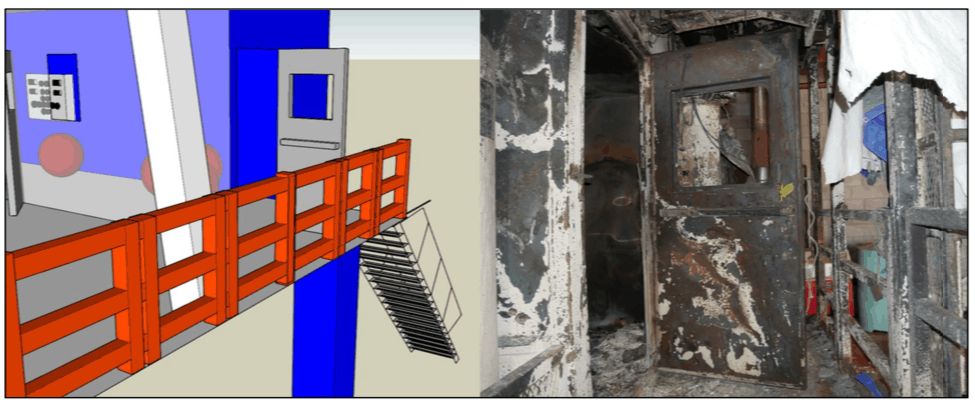

- There was no escape route out of the dog house (driller’s cabin) except into the fire.

(blowout preventer controls that failed due to melted hoses caused by fire damage)

(blowout preventer controls that failed due to melted hoses caused by fire damage)

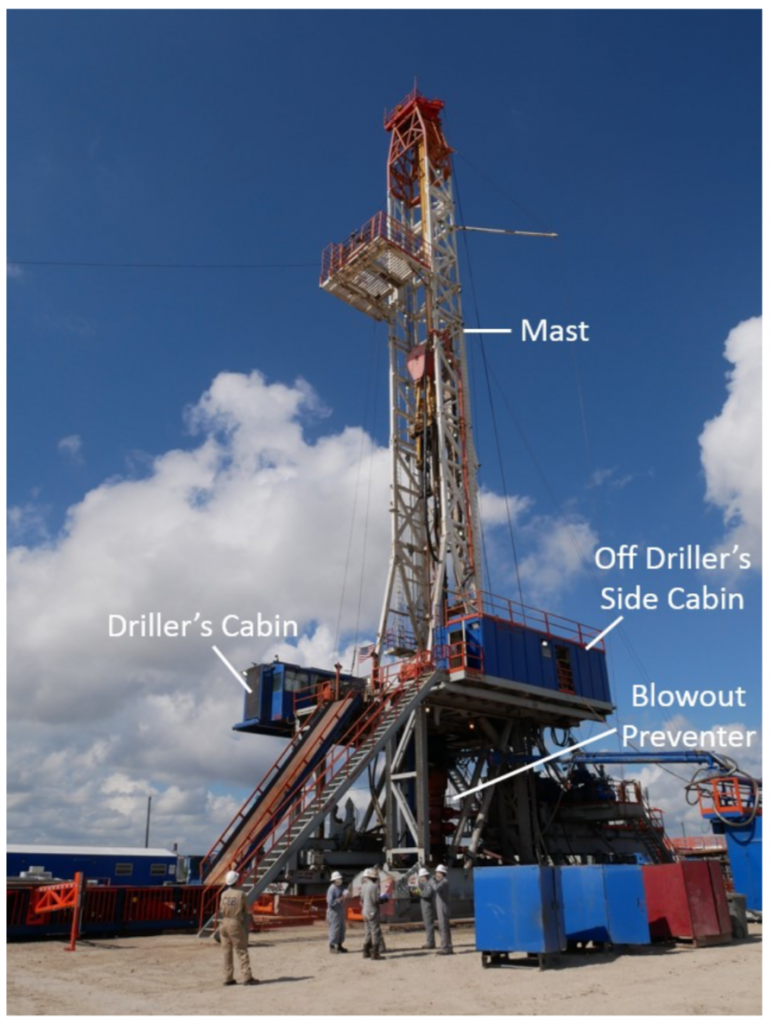

The pictures below show the problems with the escape routes…

The result was the death of 5 workers.

The detailed report provides insight into the failure of several safeguards and recommends improvements that should have been a part of any high-quality operations. Several of the failures were the result of not following company procedures and disabling alarm systems because of nuisance alarms (a human factors design issue).

The CSB recommended that industry organizations and the government develop guidance and regulations to enhance safety. But when the already existing systems and practices were not being applied, it makes one wonder if additional regulations would have had any impact.

In addition, many well blowouts mention that crews failed to detect the blowout in a timely manner. This was true in this accident and in the Deepwater Horizon accident. The report mentions the disabling of alarms and the failure to detect gas entering the well with the instrumentation provided. This indicated potential human factors design issues may be a generic problem for the drillers displays (in addition to the failure to properly perform the required flow checks).

Can a company or an industry develop solutions for these basic root causes or does a federal mandate (a regulation) need to be developed to stop blowouts and make every industry participant improve?

Read the report and let me know your thoughts – about the accident and the suggestion to increase regulations – by leaving a comment.