Metro Blue Line Train Derailment – Equipment Repeat Failure?

What is a Repeat Failure?

TapRooT® Users know that on the Root Cause Tree® under the Equipment Difficulty Category there is something called “Repeat Failure.”

The definition for the category (in the form of a question) is:

Was the equipment difficulty:

- Known to have occurred in the past; and

- Did previous failures occur frequently enough that they should have been recognized as repetitive; and

- Was there enough time since the failure that it should have been recognized as repetitive so that management should have implemented interim compensatory actions or effective corrective actions to prevent recurrence of the problem?

Metro Blue Line Derailment

How would you answer the questions above with this information?

- At 4:51 on October 12, Train 407 (eight series 7000 cars) derailed between Rosslyn and Arlington Stations.

- Train 407 had derailed two previous times that same day. In both cases the cars rerailed themselves and the derailment wasn’t detected until the NTSB inspections started after the accident.

- The NTSB stated that WMATA (operators of the train) was aware of a problem with the wheel axel assembly of the 7000 series railcars going out of alignment before the week that this derailment occurred.

- The 7000 series railcars had 52 failures due to alignment issues since 2017 (21 of which were uncovered by inspections after the accident). These are preliminary numbers and may go up.

- The NTSB discovered that in their new positions on the axel, the wheels encountered switches differently than how they were designed, causing the cars to derail as they passed through switches.

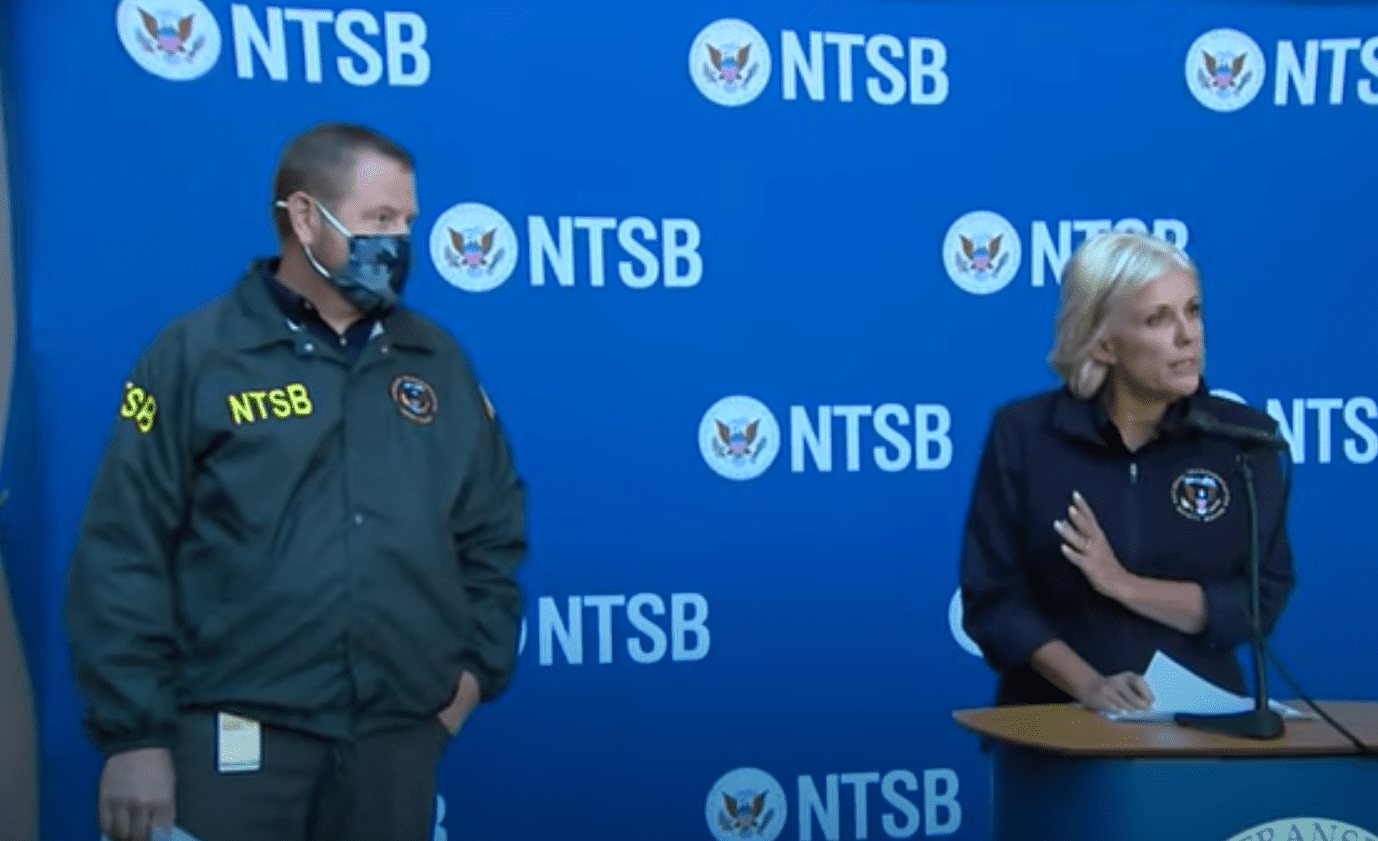

Here is a video about the wheel problems:

Was this a repeat failure by the definition above? Leave your answer in the comments below.

Interim Compensatory Actions

Metro CEO and General Manager Paul J. Wiedefeld said in a letter to employees that they were going to inspect all the 7000 series railcars before they return them to service:

“That means we identify any wheels out of alignment, isolate the cars securely, and have a data-driven plan for more frequent inspections of the fleet, and ultimately, identify the root cause.”

That sounds like an interim compensatory action to me. Is it enough to resume using these cars when complete? Again, leave your answer below in the comments.