Do You Waste Time Investigating Minor Incidents?

Wasting Time Investigating Minor Incidents

You’ve heard it before. Every minor issue needs an incident investigation and root cause analysis. First-aid cases, OSHA recordables, lost-time injuries—from paper cuts to fatalities, you must do root cause analysis. Or, at least, a mini-root cause. Do you feel you are wasting your time investigating minor incidents that really shouldn’t be investigated?

Let’s discover how you may be wasting your time and how you can apply some effective strategies to STOP wasting time.

Do Root Cause Analysis on Everything?

Why does management want you to do root cause analysis on everything?

The theory goes like this…

- Every major accident is preceded by minor incidents.

- If we identify the minor incidents and fix them, we can prevent major accidents.

- Therefore, we need to investigate and fix every minor problem to stop major accidents.

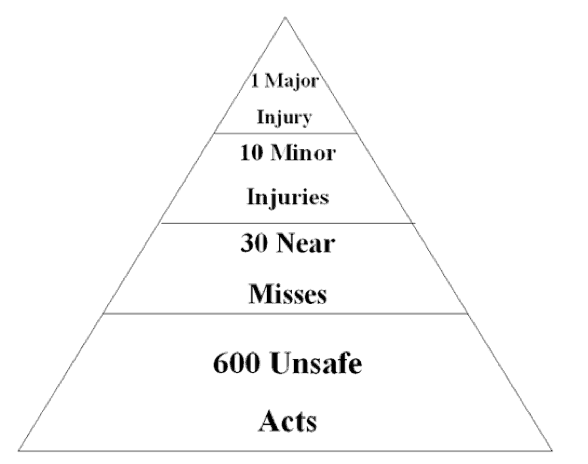

Some think this idea came from the “Accident Pyramid.”

The pyramid above came from Frank Bird’s (Loss Control Management: Practical Loss Control Leadership, 1969) modification of Heinrich’s “Foundation of a Major Accident” pyramid (see below)…

Are these pyramids an accurate display of how minor incidents lead to (or are precursors of) major accidents?

To read more about this, visit this article:

But, to make a long story short, where did safety folks go wrong? Both Heinrich and Bird were trying to say that the causes of major accidents could be the same as the causes of near-misses, unsafe acts, or no-injury accidents. The problem was some people started thinking that every minor injury, near-miss, OSHA recordable, or first-aid case needed to be investigated and fixed. But the reality is that many minor incidents have nothing in common with major accidents or fatalities.

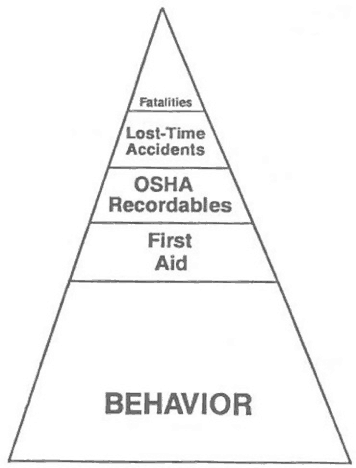

(Krause, Hindley, and Hodson Pyramid, The Behavior-Based Safety Process, 1990)

Wasted Time Investigating Minor Incidents

However, not every minor injury, near-miss, OSHA recordable, or first-aid case is a precursor to a major accident (or even a serious injury). Thus, investigating paper cuts is a waste of time if you are trying to prevent major accidents and serious injuries. A paper cut will never become a major accident (or at least it is highly unlikely).

Thus, the first way you waste time investigating minor incidents is wasting your time investigating incidents that don’t have the “seeds” of a major accident in them. In other words, there are many causes of first-aid cases that will never be the cause of a fatality. It would be a waste of time to investigate these unimportant first-aid cases if your goal is fatality prevention.

Wasted Time Fixing Minor Incidents

But what is worse than wasting time investigating minor incidents? Wasting time fixing things that were never going to cause a major accident.

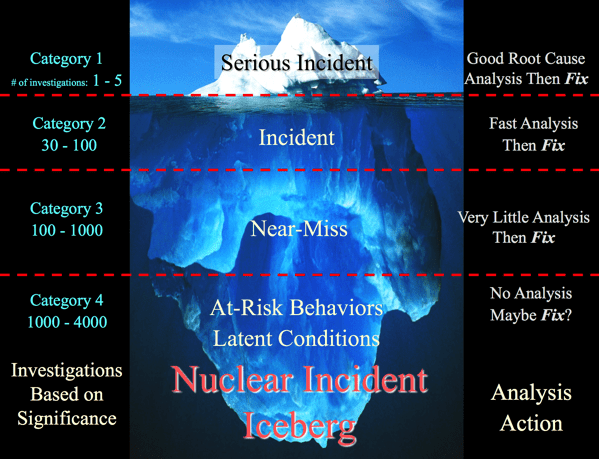

This fixing of minor problems that will never cause big accidents eventually led to what we see as the Nuclear Incident Iceberg.

The nuclear industry got the idea that investigating everything was a great idea. But they realized that they couldn’t do a root cause analysis of everything. So they started doing less thorough investigations called an ACE or an Apparent Cause Analysis. We wrote about this back in 2006 in an article titled: The Curse of Apparent Cause Analysis.

What is “the curse”?

The curse is that we waste time fixing the root causes of poorly investigated minor incidents that probably aren’t the real root causes of the minor incidents. Worse yet, these causes probably would never lead to major accidents but we fix them anyway. These fixes go into a tracking system and people waste a tremendous amount of time/effort implementing the fixes for the “fake” root causes.

In some cases, people realize the fixes are a waste of time, and a backlog of fixes starts to develop. The backlog is a mixture of needless fixes and important fixes (an excess of more needless fixes than important ones). Because of the backlog, important fixes get delayed (or never implemented), while time is wasted on useless activity.

Thus, wasting time implementing needless fixes is a super waste of time.

By the way, the nuclear industry is trying to reduce the number of investigations they do into minor problems. Read more about it HERE and HERE.

What Should You Do to Investigate Minor Incidents?

There is an easy answer to this question. We wrote a book about it:

Using the Essential TapRooT® Techniques to

Investigate Low-to-Medium Risk Incidents

And we built a course to teach you what to do:

2-Day TapRooT® Root Cause Analysis Training

The key to the investigation of minor incidents is to only spend time investigating minor incidents that are worth investigating to prevent major incidents.

How do you do that?

First, you must collect enough information about the minor incident to decide if there is something that can be learned to prevent a major accident. You do this by collecting information and organizing it on a SnapCharT®. That’s the first step in the process to investigate low-to-medium risk incidents.

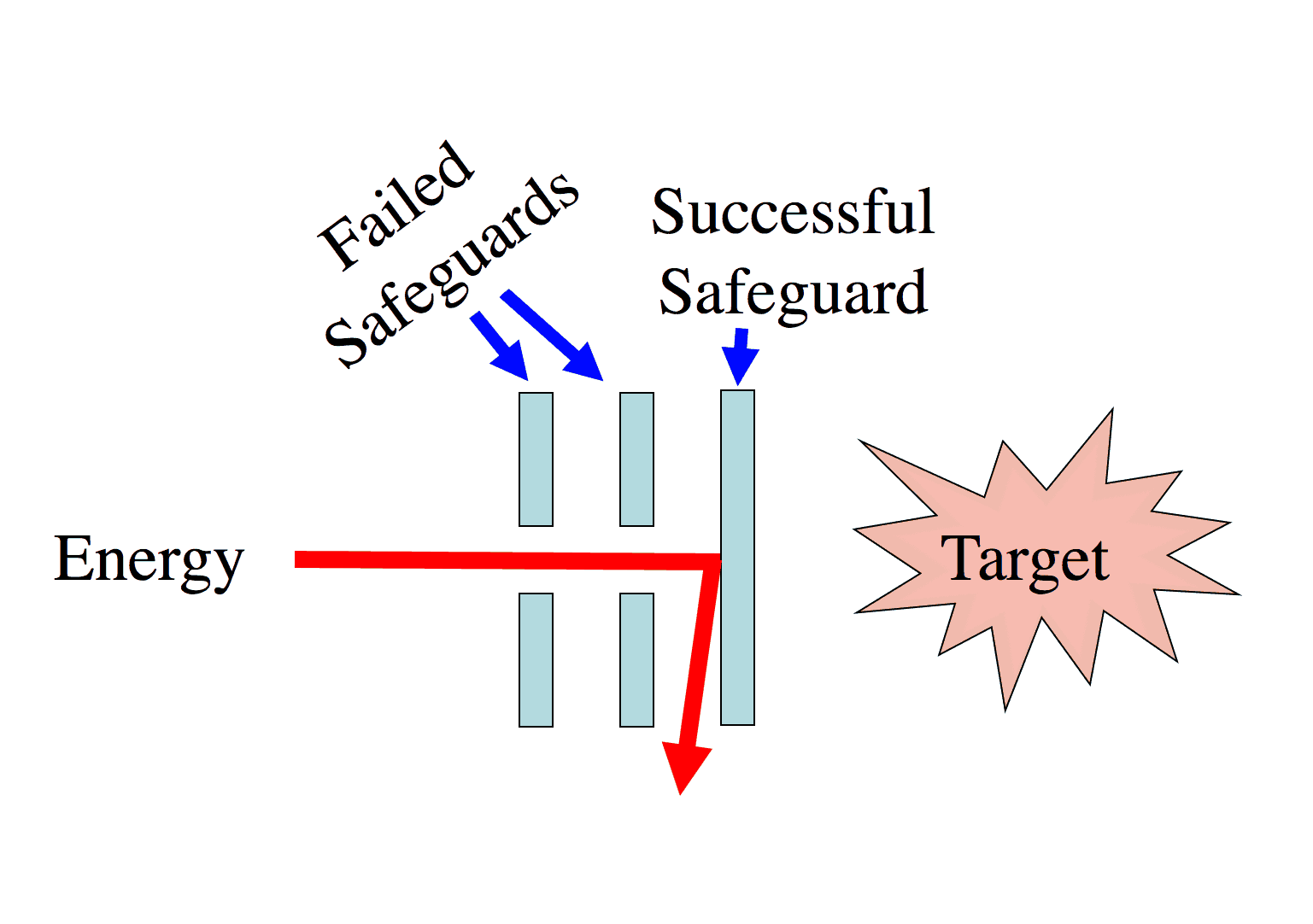

The next step is to decide if there is something to learn from this minor incident. One way to decide is to consider the Safeguards that had failed.

The first thing to do is to analyze the risk presented by the Hazard (Energy) and the value of the Target. For example, if the risk was high-voltage electricity and the Target was a person, you might want to have several highly reliable Safeguards.

For a minor incident, at least one Safeguard prevented the minor incident from becoming a major accident (as shown in the diagram below)…

You need to decide if that single Safeguard (or a combination of Safeguards) is strong enough to consistently keep the major accident from happening. If there is an unacceptable risk after the other Safeguards had failed, you should probably continue to analyze the incident by identifying the Causal Factors and finding their root causes using the Root Cause Tree®.

Where you will save effort and time is if you decide that the investigation isn’t worth continuing (nothing to learn). This could be because the Hazard isn’t very threatening, the Target isn’t that valuable, or the remaining Safeguard is really strong. In those cases, you don’t continue the investigation and you don’t fix anything. Thus, you save tremendous amounts of time and effort with no loss in learning. (There was really nothing to learn from the minor incident.)

Even if you continue the investigation, we have only included the essential TapRooT® Tools in the process so that investigators save time and effort in their initial training and in their use of the tools during the investigation.

Learn More About Using TapRooT® for Minor Investigations

Want to learn more about using the essential TapRooT® Techniques to find the root causes of minor investigations? See the list of our upcoming public TapRooT® Training at this link:

https://www.taproot.com/store/Courses/

The 2-Day TapRooT® Course teaches the essential TapRooT® Techniques for investigating low-to-medium risk incidents.

The 5-Day TapRooT® Course teaches both the essential techniques and the process to investigate low-to-medium risk incidents, and the complete TapRooT® Techniques and the major investigation process.

In any Industry / work place First Aid / Reportable Incident/ Lost Time Accidents / Fatalities linkage intesity with lack of comptencies of working pesron at job site ?

Does education of working crew matters

In any Industry / work place First Aid / Reportable Incident/ Lost Time Accidents / Fatalities linkage intesity with lack of comptencies of working pesron at job site ?

Does education of working crew matters for safety excellence ?

If so then how mucth ?

Thanks for the info, I truly believe field time is more valuable than spending hours on insignificant low-risk events.