Why is Picking the Right Root Cause Analysis System so Important?

Did They Pick the Right Root Cause Analysis System?

Once again, I was struck with the importance of picking the right root cause analysis system. Why was I “struck?” Whenever I see an industrial accident with a fatality, I can almost guarantee the company has weaknesses in its root cause analysis of previous precursor incidents. The company probably has a misunderstanding about the fundamentals of root cause analysis.

Of course, you don’t have to take my word for this. After the Texas City Refinery explosion, the Baker Commission published a report that included this quote:

On page xiv of the report: “Although BP is improving aspects of its incident and near miss investigation process, BP has not instituted effective root cause analysis procedures to identify systemic causal factors that may contribute to future accidents. When true root or system causes are not identified, corrective actions may address immediate or superficial causes, but not likely the true root causes. The Panel also believes that BP has an incomplete picture of process safety performance at its U.S. refineries because BP’s process safety management system likely results in underreporting of incidents and near misses.“

Doesn’t that sound like what I am saying?

What Happens if You Pick the Wrong RCA System?

If you pick an ineffective root cause system, you won’t find and fix the real root causes of incidents.

Your people might THINK they are finding root causes, but the uncorrected root causes that your investigators miss will come back to haunt you when the problems cause a fatal accident. After all, BP employees at the Texas City Refinery thought they were finding and fixing the root causes of their precursor incidents, but they didn’t prevent a major accident.

DON’T LET THIS HAPPEN TO YOU!

How do you correct the weakness in your root cause analysis processes?

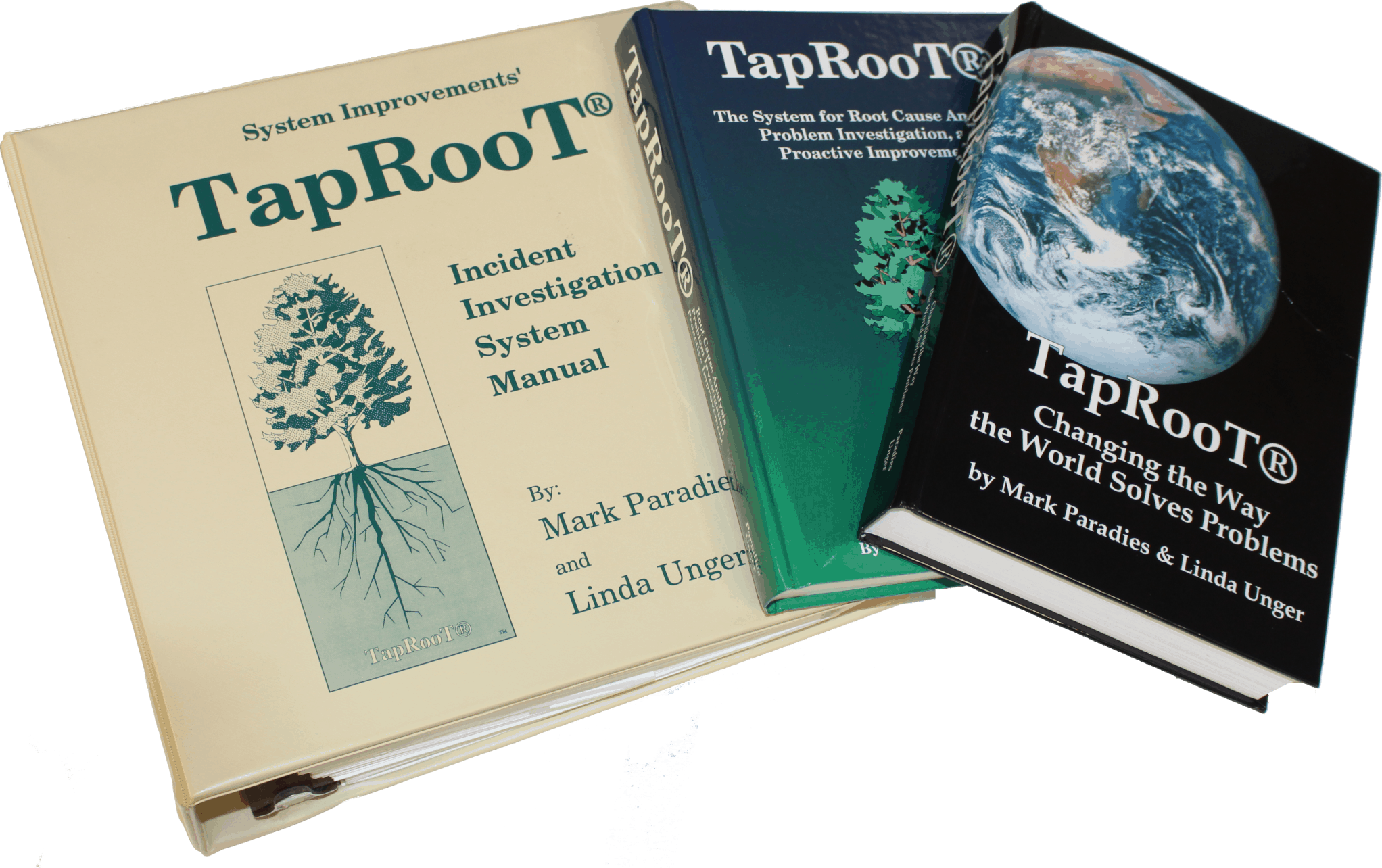

I started that journey in 1985. It eventually led me to use my knowledge of human factors and equipment reliability to create the TapRooT® System. By 1991, we had a TapRooT® Manual and our first 2-Day TapRooT® Course. And that was just the start of our journey. We keep making the TapRooT® System better every day.

Over the years, we have learned from our research, client feedback, experience using TapRooT®, and course feedback (we train about 10,000 people annually). We put the knowledge we gain to work by improving the TapRooT® System year after year.

We start by improving our various TapRooT® Courses.

Also, when we get new ideas to share, we write new books (TapRooT® Manuals, TapRooT® Books, Root Cause Tree® Dictionary, and Corrective Action Helper® Manual). For example, we wrote the original TapRooT® Manual in 1991. And then…

- TapRooT® Manual was revised in 1992.

- TapRooT® Manual was revised in 1994.

- TapRooT® Manual was revised in 1996.

- TapRooT® Book (hardcover was written in 2000.

- TapRooT® Book was revised in 2008.

- TapRooT® 10-book set was written starting in 2015.

To learn even more from our users and spread the word about the latest TapRooT® improvements and other ideas about performance improvement, we sponsor the Global TapRooT® Summit. This is a great place to benchmark your root cause analysis system and get new ideas for improvement.

That’s how we keep the TapRooT® System the best root cause analysis system in the world. That’s how you can be confident that you are picking the right root cause analysis system.

Pick the Right Root Cause Analysis System

To implement the right root cause analysis system, attend TapRooT® Training.

For people in charge of their root cause analysis program, I recommend the 5-Day TapRooT® Advanced Root Cause Analysis Team Leader Training. Here is a link to the location and dates of our public 5-Day Courses being held around the world:

http://www.taproot.com/store/5-Day-Courses/

Continuously Improve Your Root Cause Analysis

We continuously improve the TapRooT® Root Cause Analysis System. Do you continuously improve your knowledge and application of the TapRooT® System?

If you have already attended only a 2-Day TapRooT® Class, go to the 5-Day (link above). You will learn advanced techniques and practice your TapRooT® skills.

Are you still using an old TapRooT® Book? Order a complete set of the newest books at this link:

But don’t stop there. Continuously improve your use of the TapRooT® Root Cause Analysis System by learning and applying the latest improvements in the system. Attend the next Global TapRooT® Summit to:

- Learn about the latest improvements to the TapRooT® System,

- Network with other TapRooT® Users,

- Share best practices and

- Be inspired to take your root cause analysis to the next level.

Help your investigators do a better job finding and fixing the causes of smaller incidents (precursor incidents) to stop major accidents by applying the right root cause analysis system – TapRooT®.

(This article was revised and republished from the original published in 2018. We believe the lessons learned are just as applicable today. We hope you learn and enjoy.)

Can I order the books. And if I can should I start with number 1 or is this old information.

Thank you very much.

Randy Dixon SHE Professional

Yes

In a few months we will have a boxed set out (Books 1 – 10).

I would start with 1, 2, 3, and 4, and read them in that order.