Why would you reject a root cause analysis report?

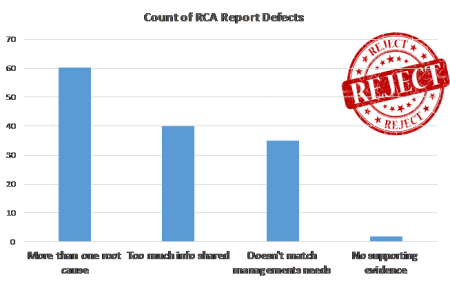

While we probably would not see a frequency chart in real life like the one above, we all have seen or perceived the above rejection reasons after sending in our root cause analysis report to senior management or a regulator. Below are a few reasons that have caused a report or corrective action in a report to be rejected.

1. Rejection Example 1 (FDA):

We have reviewed your firm’s response of February 3, 2010, and note that it lacks sufficient corrective actions.

Specific violations observed during the inspection include, but are not limited, to the following:

1. Your firm has failed to reject drug products that did not meet established standards or specifications [21 C.F.R § 211.165(f)].

In your response, you state that this product is no longer manufactured and that such practices do not represent your company’s current CGMP compliance standards. You have committed to have all current and future investigations reviewed and signed by the Vice President of Quality Operations. However, you did not review your records to ensure that other products that failed to meet AQLs were not distributed. In addition, your response does not include training of the QCU to ensure that they are capable of identifying and ensuring appropriate corrections of these types of discrepancies in the future.

Problem Assessed: Company did not look for extent of condition (generic/systemic issues) or a complete corrective action with follow through.

2. Rejection Example 2 (NRC)

Company failed to correct CAPA 15-171, closed November 30, 2015, for finding 60010. CAPA 15-171 corrective actions required a revision to work instructions to include a pressure setting for contact blocks 60010. After discussions regarding the pressure setting with Company quality inspectors, the NRC inspection team identified that Company had not updated the work instructions.

Problem Assessed: Original finding did not get addressed nor were there any root causes identified for the original issue.

Just like students in a classroom, each report writer learns what the senior executive or regulator expects when writing an investigation report, often through trial and error. Often in some industries it seems that more time is spent writing an investigation report than is spent on the actual investigation.

How can you reduce the number of rejections that you might face while still ensuring a concise root cause analysis with effective corrective actions. Follow the steps below.

1. Do not let the written report criteria drive the root cause analysis itself.

• Perform the root cause analysis using an unbiased process like we do in a TapRooT® investigation.

• Collect the type of information that is required for the written report however do not limit what is collected.

2. Define the criteria for each section of the written report and hold that criteria true when writing a report.

• There should be little overlap in terms such as Causal Factor, Root Cause and Incident. In other words, no gray areas for interpretations.

• When within your control, reduce redundancy in your written report.

3. The written report should be concise and include enough information to be a standalone document as needed for the audience reading it. There should be no doubt when reading a report as to:

• What was the incident

• What led up to the incident

• What was the response to the incident

• What were the causal factors for the incident

• What were the root cause for the incident

• How each root cause will be addressed, whether eliminated or mitigated.

While there will be additional criteria required by the report requester for the writer to meet, the truer one stays to the purpose of an investigation and its documentation, the higher the chance of reducing said incident in the future.

Want to learn how to create a paperless report? Check out our series here.