Don’t Be Fooled By a Good Talk

Talking and Doing Are Different Things

You may have seen them. Slick talkers. They make a presentation to senior management and then … there you go – chasing the next flavor of the month improvement initiative.

You may even get some initial improvement because of the Hawthorne Effect or Regression to the Mean.

How many of these high-priced programs with lots of talk and no substance will you implement before you learn your lesson? And how many good programs were discontinued because management wanted to chase the newest program?

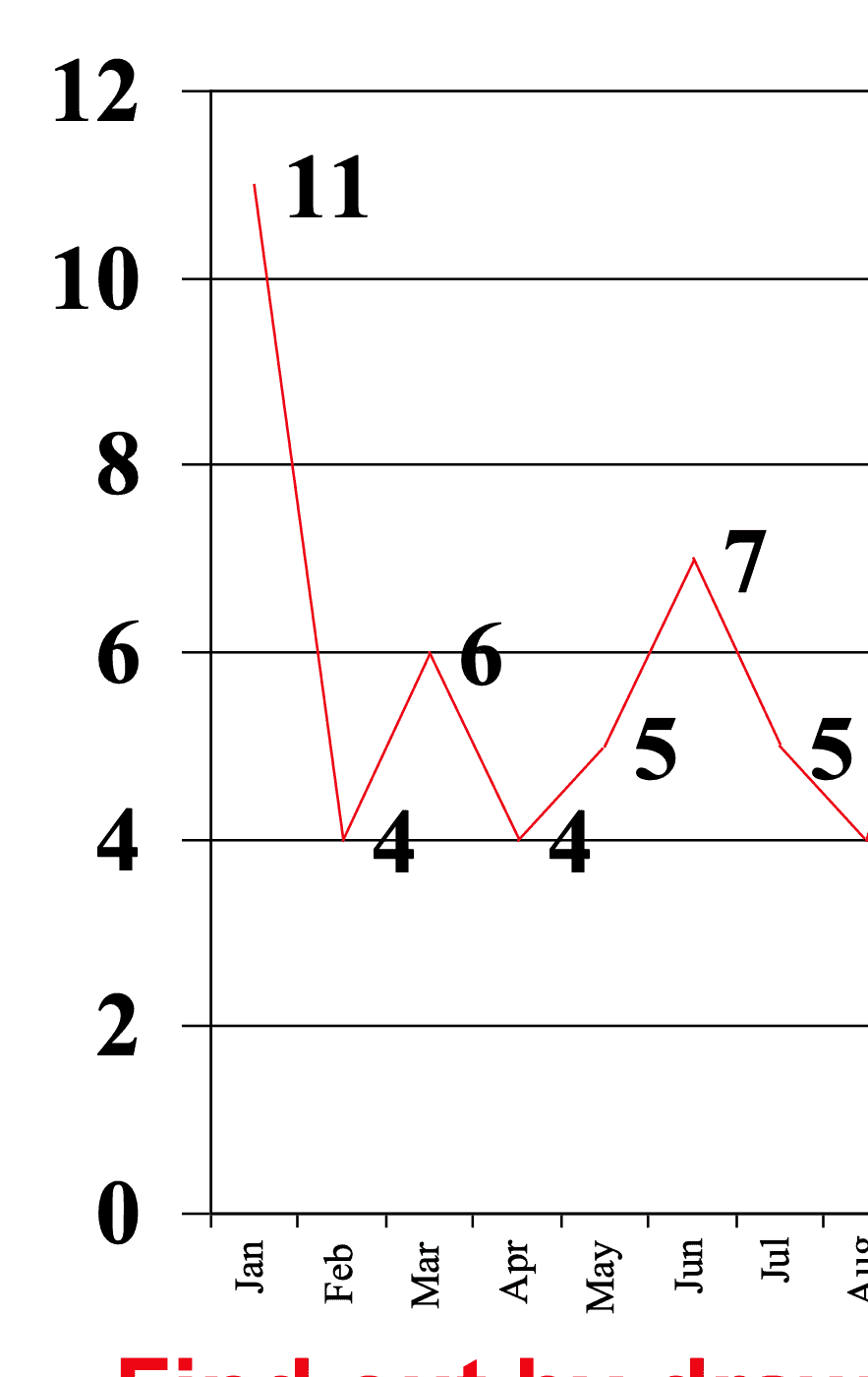

Safety Improvement Example

At this site, safety had really turned around. The site had a bad month in January with 11 safety incidents. But the management held a safety standdown with a video about safety being a condition of employment. They told everyone to be safety conscious. And it worked! For the next few months (with the exception of June) performance improved!

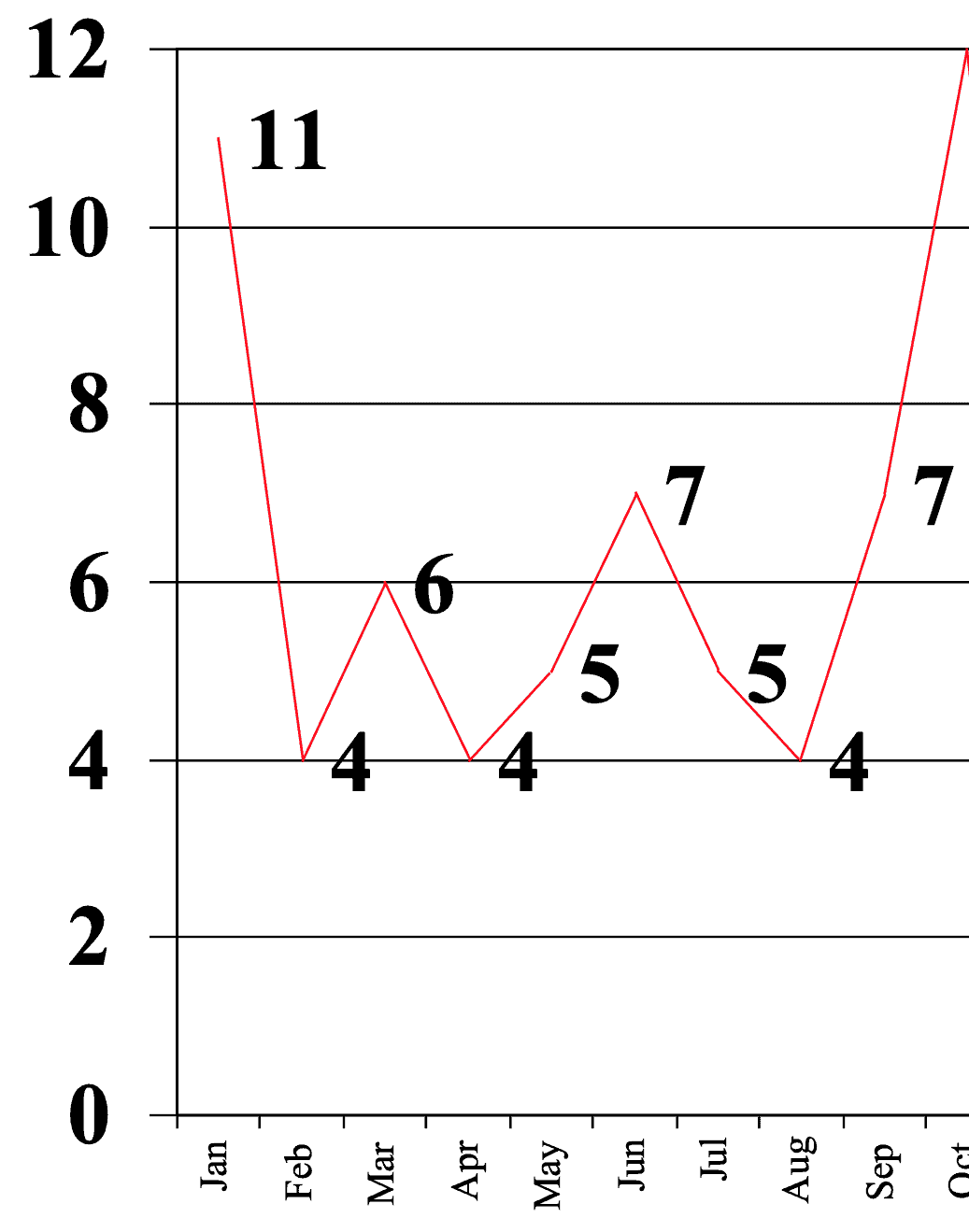

But then it happened … Performance got way worse. Employees must have become complacent. The site had a month with 12 safety incidents.

Luckily, senior management just had an excellent presentation from a slick-talking Ph.D. consultant about the latest techniques to stop errors and improve safety. The new technique was expensive but, as the consultant explained, it is worth it to improve safety.

The site implemented the new technique on an expedited basis (the next 2 months). And the news thereafter was great. While they were finishing implementation, the site had a new record low of 2 incidents per month. They had a slight slip back to higher numbers but the stats went back down to 2 again for two months in a row!

So obviously, the new technique worked … Right?

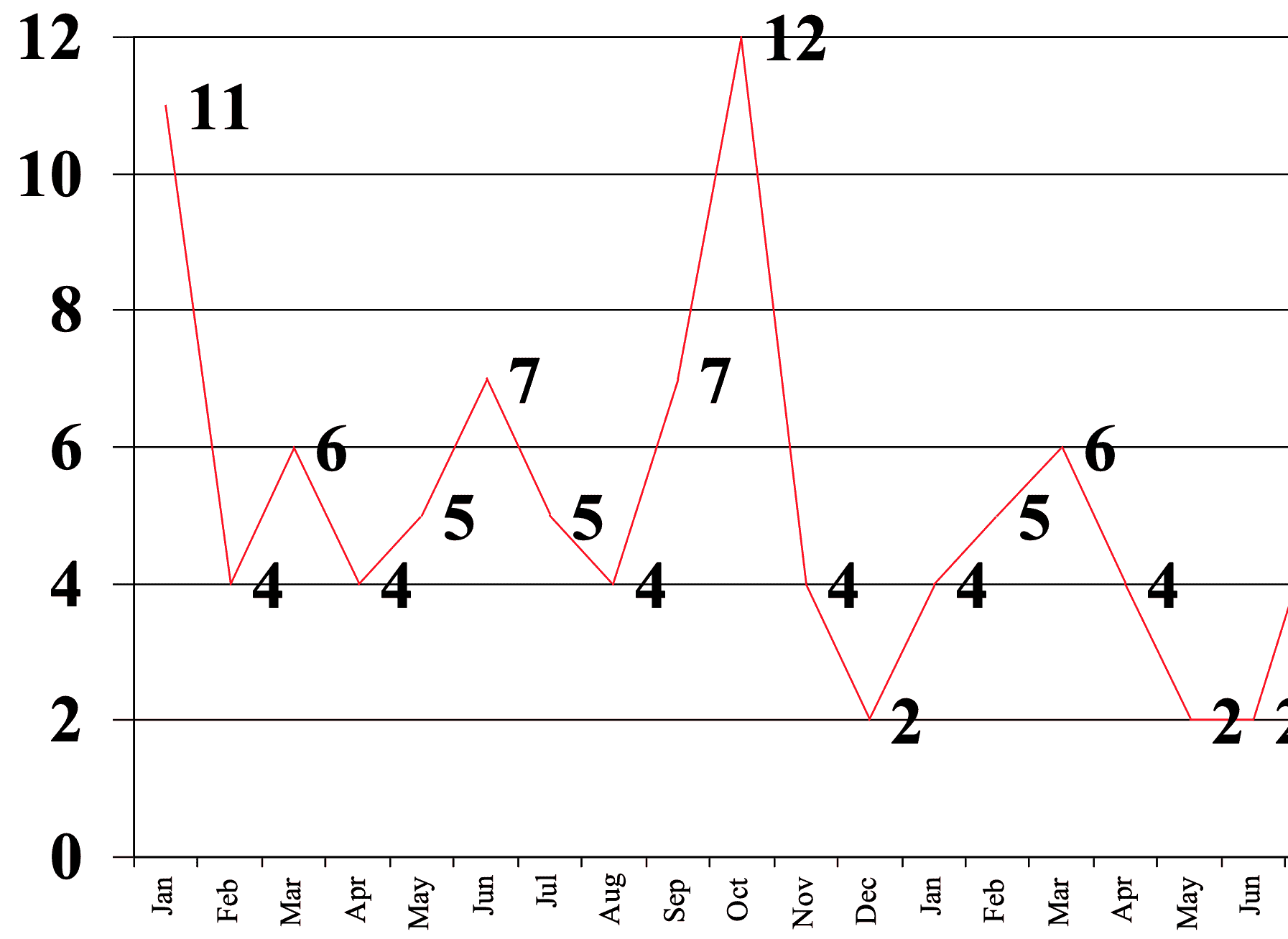

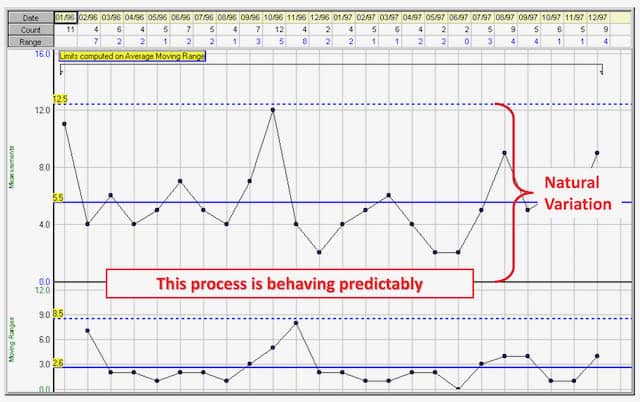

Well, here is the whole graph…

If you aren’t familiar with a Process Behavior Chart, it shows that there was no real improvement. All of the performance (from the 12 incident month to the 2 incident months) was within the expected performance of the system.

In other words, the standdown and video didn’t “cause” performance to improve. People didn’t “get complacent.” The new Ph.D. consultant’s program didn’t “cause” improvement. Just like they explained in the video above, management was fooled by regression to the mean.

How Do You Know What Improvement Program to Choose and If That Program Works?

First, you should learn how to evaluate performance using the Process Behavior Chart. You can get a book, Performance Measures and Trending for Safety, Quality, and Business Management, about selecting performance measures and tending them using Process Behavior Charts here:

Then you can measure your improvements reliably and tell when significant improvement occurs with whatever program you choose.

Guarantee

Next, you should ask if there is a guarantee?

Here is our guarantee for TapRooT® Training:

Attend our Root Cause Analysis Training. Go back to work, and use

what you have learned to analyze accidents, incidents, near-misses,

equipment failures, operating issues, or quality problems.

If you don’t find root causes that you previously would have overlooked

and if you and your management don’t agree that the corrective actions

that you recommend are much more effective, just return your course

materials and we will refund the entire course fee.

If your program is guaranteed, you can relax knowing that at least the provider is confident about the results.

References and Success Stories

Also, ask to talk to references that have been using the technique for 5 or 10 years. See what results they have achieved and make sure that the results aren’t just regression to the mean.

Here are some TapRooT® User Success Stories that demonstrate consistent improvement over a number of years.

The first is a program that cuts ergonomic injuries…

They continued to use TapRooT® RCA to this day and expanded their success to facilities around the world.

The second program is an example of process improvement and bottom-line results…

They continued to use TapRooT® RCA to achieve excellent financial results until mergers and corporate reorganization forced them to adopt a new system developed by “corporate.” (However, the local site continued to use TapRooT® RCA in secret and convert their analysis into the less effective system. This continued until the TapRooT® Trained Users left the site.)

And here is another safety improvement example that provides statistics over a seven-year period…

Hearing about others’ success will help you feel confident that you, too, can succeed.

Research and Development

Ask the people selling the new improvement techniques how they continuously improve their techniques and support continuous improvement of the use of the techniques at their clients’ sites.

For example, here are the improvements we made to the TapRooT® System in the past year…

How do we get suggestions and advice on making improvements to the TapRooT® System? First, we have the TapRooT® Advisory Board made up of 60 clients from around the world. They help us develop and evaluate improvement ideas.

Second, we listen to our students. We train thousands (close to 10,000) students per year and they provide us with feedback, ideas, and suggestions to make the training and software better.

Third, we sponsor an annual TapRooT® Global Summit to:

- Help our users keep up with the latest improvements in TapRooT® System,

- Provide us with feedback and best practices,

- Help our clients meet new people and share best practices from around the world,

- Share other best practices that we have learned from our extensive knowledge of performance improvement success stories. These include improving human performance, quality, operational excellence, asset reliability, and safety.

The history of System Improvements and TapRooT® RCA is one of excellence and continuous improvement. We are continuously making the best root cause analysis system even better.

So if the program you are evaluating has a track record of results and investing in continuous improvement, you can feel confident that future results will continue to be excellent.

Learn to Use TapRooT® Root Cause Analysis to Make Your Improvement Efforts Excel

We won’t use slick talks and regression to the mean to make you think you are experiencing improvement. We have a well-researched, continuously improved system with proven results. TapRooT® Root Cause Analysis will help you improve performance and continuously improve over the years to gain the operational excellence, safety performance, asset reliability, and quality results that you need in the current competitive world.

See our COURSES and pick the ones that will help you achieve excellence. Or contact one of our implementation experts by calling 865-539-2139 or by CLICKING HERE to discuss your plans and set up an executive briefing.

Don’t be fooled by the “latest” technique and a slick talk. If you are interested in:

- Improving Safety

- Stopping Human Error

- Improving Asset Reliability

- Achieving Operational Excellence

- Consistently Improving Quality

Then now is the time to try a proven system based on decades of research and development and continuous improvement. Register for a TapRooT® Course TODAY!