How Can We Help Your Improvement Efforts? (More ways than you might think!)

What Are Your Improvement Goals?

If part of your job is to stop bad things from happening, we can help. Look at this list of objectives. Are any of them part of your improvement goals?

- Prevent fatalities

- Improve quality

- Improve your root cause analysis

- Investigate a difficult incident

- Solve equipment reliability issues

- Improve profitability

- Reduce lost time accidents and workers comp costs

- Stop sentinel events and improve healthcare quality

- Improve process safety

- Meet senior management improvement expectations

We can help.

How? We have helped companies all over the world implement TapRooT® and train their personnel to use advanced root cause analysis to solve difficult problems. This has caused us to get involved in all types of performance improvement initiatives. We have facilitated difficult investigations. We’ve analyzed trends. We can help you become proactive.

Here are some examples of ways we can help…

IMPROVE YOUR TapRooT® IMPLEMENTATION

We wrote the book on implementing TapRooT®.

We know how it should be used and the best ways to improve its use.

We see best practices from around the world, and we can help you get started the right way and improve your use of TapRooT® even if you have been using it for years.

How do you get started? Call us at 865-539-2139. We’ll be glad to listen to the issues you face, what you’ve done so far to make improvement happen, and explain what you can do to take your program to the next level.

INVESTIGATION FACILITATION

Do you have a tough, controversial, or serious incident that you need help investigating? Is your root cause analysis stuck? We can help!

Our instructors are experts in applying TapRooT® to investigate problems. accidents, incidents, quality issues, sentinel events, equipment issues, production problems, and cost overruns. We don’t “do” investigations. But we can supply an experienced TapRooT® facilitator to help your team with a tough investigation or to review an investigation that is nearing completion.

Call us at 865-539-2139 or CLICK HERE to drop us a note to start the process.

BECOMING PROACTIVE

Using TapRooT® to investigate accidents and stop them from happening again is good. But is even better to use TapRooT® to stop accidents from ever occurring by being PROACTIVE.

Do you need help making your root cause analysis be more proactive? We can help.

We can show you how to apply TapRooT® proactively to stop accidents, incidents, quality issues, equipment reliability problems, production problems, or sentinel events. We have a specific course to teach the skills you will need to apply (2-Day Auditing & Proactive Improvement Using TapRooT®). You can attend the public course (the next one is scheduled on April 24-25 before the 2023 Global TapRooT® Summit). Or you can contact us to have a course at your site (which we can customize to fit your needs perfectly).

We would be happy to work with you before the course to get your proactive program set up to take advantage of the tools that TapRooT® RCA offers.

ANALYZE TRENDS

Need help analyzing your performance trends? We can Help.

Not only do we teach a course on advanced trending techniques (2-Day Auditing & Proactive Improvement Using TapRooT® RCA). Our next public course is on April 24-25, 2023, just before the Global TapRooT® Summit. Or you can sponsor a course at your site. Then, we can help you apply those techniques to analyze your performance issues and help you present the findings to your management.

We’ve found that many TapRooT® Users have never had experience in using trends to target improvement initiatives. So we can give you the training you need to understand trending and help you do your first trend analysis to understand how trending can be applied to prevent problems.

Call us at 865-539-2139 or drop us a note to find out what we can do to help you look at your trends.

SOFTWARE IMPLEMENTATION

Need help getting the most from your TapRooT® Software? We know how to do that.

Many people use TapRooT® Software to analyze incidents. But do they get the most from their software?

We can help with up-front business analysis to properly implement the software.

Also, we offer a course – 2-Day TapRooT® Software Course – to help TapRooT® Software Administrators and TapRooT® Software Super-Users learn what is needed to set up their software for best results.

One more thing … We can also consult with TapRooT® Users and Software Administrators to help them develop a TapRooT® Software implementation plan. Call us at 865-539-2139 or drop us a note for more info about this service.

CREATE AN IMPROVEMENT INITIATIVE

If you are considering starting a new performance improvement initiative, why not get us involved from the ground up? We can help!

We can use our knowledge of improvement programs from around the world to help you implement a world-class initiative.

We can also bring in experts that we have worked with in equipment reliability, aviation safety, construction safety, nuclear safety, human factors, process safety, lean/six sigma, and patient safety to give your program a head start.

Don’t try to reinvent the wheel. Let us help you get ahead of the game. Call us at 865-539-2139 to discuss your program and find out how we can help you succeed.

Building a Roadmap to Success

That’s just a few ideas. But whatever you are trying to improve, we can help you develop a free Roadmap to Success. We help people do this each year at the Global TapRooT® Summit, or we can work with you and your management to get your custom roadmap finalized.

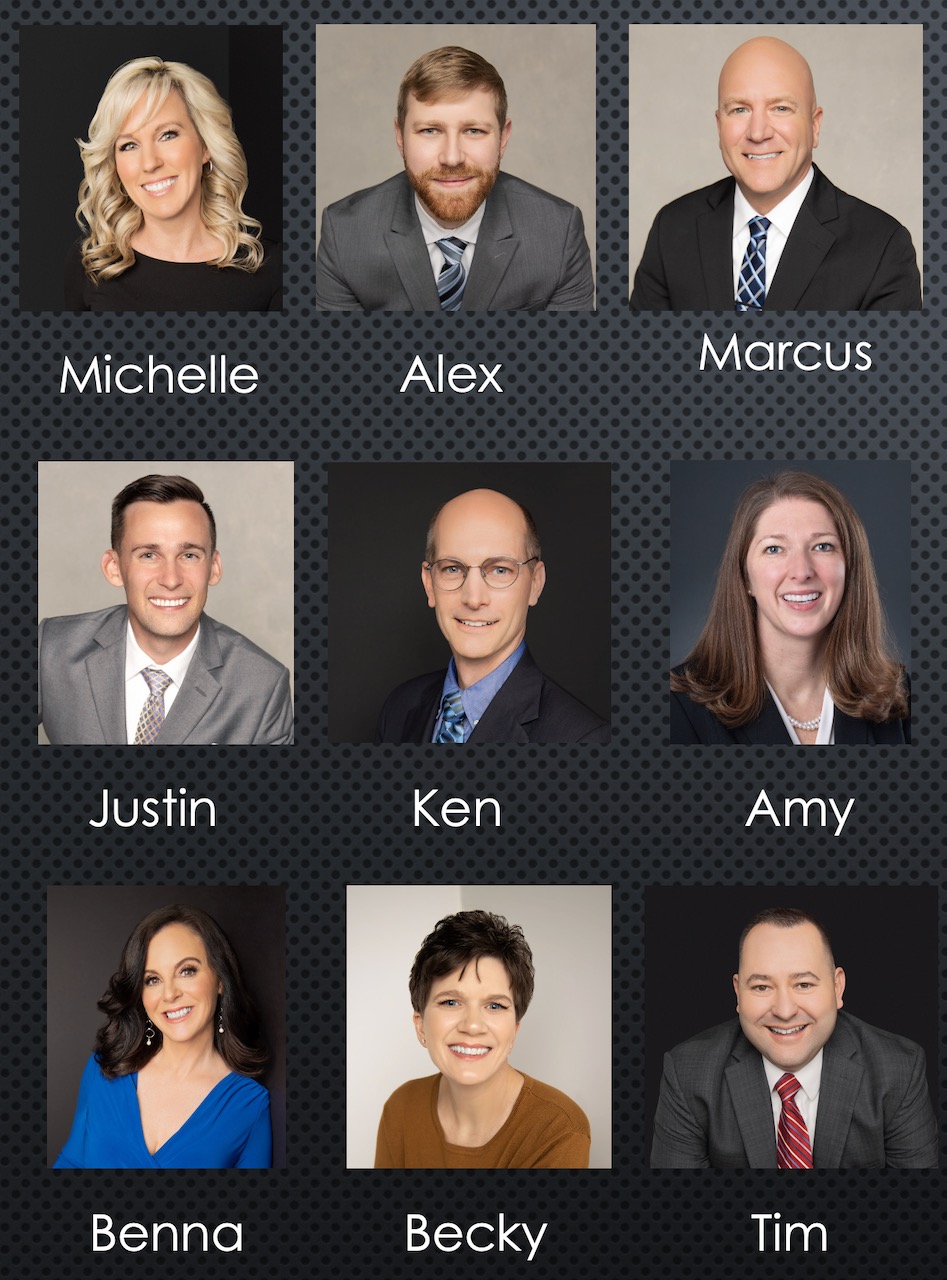

Don’t miss this opportunity to allow us to share our knowledge and make your improvement initiatives even better. Our TapRooT® Implementation Experts will be glad to help.

Call us at 865-539-2139 or drop us a note to start the process!