Runaway Rail Vehicle & Near-Miss at Dereham Station

Around 3:52 pm on December 10, 2020, a runaway rail vehicle narrowly avoided striking pedestrians and road traffic on Norfolk Road level crossing at Dereham Station.

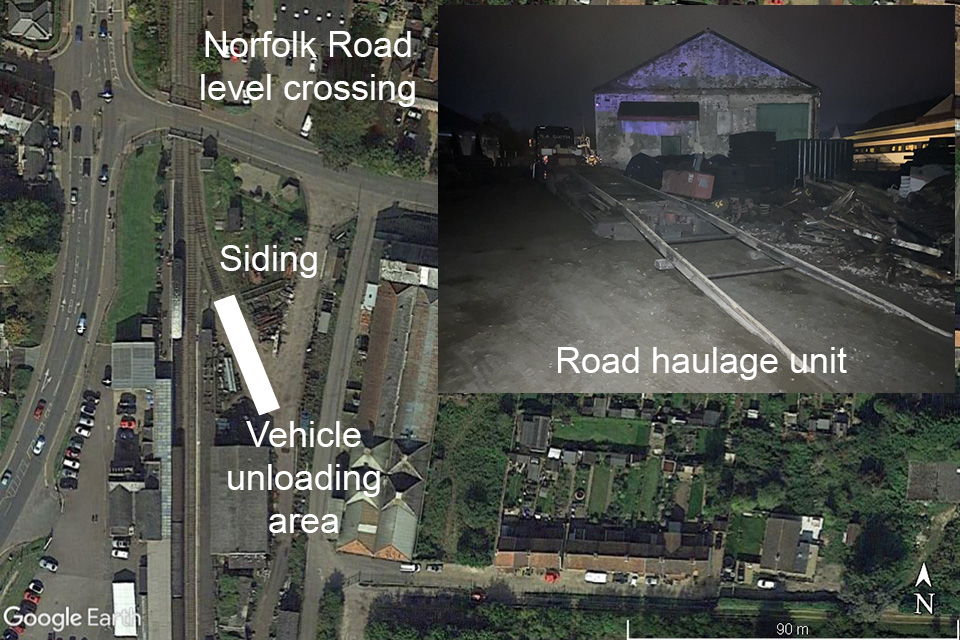

The runaway rail vehicle was the intermediate vehicle of a three-car Pacer diesel multiple unit that was being delivered to the station by road haulage. It ran away while a winch was being used to roll it off an inclined trailer onto a siding that led to the gated level crossing. The level crossing was open to road users at the time. No arrangements were in place to prevent the runaway vehicle reaching the level crossing.

The Pacer runaway vehicle arrived at Dereham resting on rails fitted to the road trailer

The road haulage unit driver (referred to here as “the driver”) and the driver of the accompanying escort van worked together while unloading. The driver operated the winch using a remote control, while at the same time observing the Pacer vehicle. He had attached the winch rope to the vehicle using a length of chain. After the winch had taken the initial load, the escort van driver released other chains that were securing the vehicle to the road trailer. The driver allowed the vehicle to gradually roll off the inclined trailer. Around 70 seconds later, the driver heard the attachment chain drop and the vehicle ran away toward the level crossing. It was “unbraked”; there was no means of stopping it.

The vehicle ran uncontrolled for over 30 seconds . . .

. . . passing a stop board, running the wrong way through, and damaging, trailing points (which possibly slowed it down) and onto the running line where it collided with the level crossing gates. It came to a stop, blocking the road.

No one was injured. However, CCTV shows one pedestrian crossing in front of the vehicle eight seconds before it arrived at the level crossing. Altogether, around 250 pedestrians and cyclists and 150 cars, vans and buses had used the level crossing during the time that the vehicle was being unloaded.

The accident occurred because the winch rope was connected to the Pacer vehicle by a chain in a manner that did not provide a secure means of attachment and, as a result, became free. There were no suitable arrangements for mitigating the consequence of this hazard.

Unloading at Dereham was part of work to transfer a three-car Pacer unit from a depot in Worksop to the Mid-Norfolk Railway Preservation Trust (Mid-Norfolk Railway). On November 13, 2020, Mid-Norfolk Railway contracted the work to a specialist road haulier, S.A. Smith. It explained that this was one of a number of contractors it had used before for this type of work.

While contractors have their own legal duties, anyone engaging a contractor has a health and safety responsibility for both the contractor themselves and anyone affected by the work the contractor does

Health & Safety Executive guidance for managing health and safety explains that, while contractors have their own legal duties, anyone engaging a contractor has a health and safety responsibility for both the contractor themselves and anyone affected by the work the contractor does. This includes making sure everyone is provided with relevant information, understands their part in identifying and managing the specific risks from the planned work and that the associated control measures are agreed prior to the work starting.

As a result of its own investigation of the accident, Mid-Norfolk Railway has stated that it has suspended vehicle loading and unloading operations on the siding and proposes trackwork alterations that will remove direct access to the running line.

What can we learn from this accident?

This accident demonstrates the importance of:

- railway undertakings ensuring that when they contract out work:

- any information and supervision needed to plan and safely carry out the work is made available

- the specific risks arising are identified, and adequate mitigation measures put in place

- road haulage contractors, and others undertaking safety critical work on or near railway infrastructure, stopping work when the method statement does not cover the required tasks.

Read the full report of this accident. The source for this lesson learned is Rail Accident Investigation Branch (RAIB), Gov. UK, published March 16, 2021.

Register today for a TapRooT® Root Cause Analysis Training Course

TapRooT® training is global to meet your needs. If you need particular times or locations, please see our full selection of courses.

If you would like us to teach a course at your workplace, please reach out to discuss what we can do for you, or call us at 865.539.2139.

Stay engaged with your skills and training: Follow along on our blog; join our Wednesday TapRooT® TV videos at 12 pm EST; connect with us on Facebook, Twitter, Instagram, Pinterest, LinkedIn, and YouTube.

Get your team ready for the one conference you must attend in 2021

The 2021 Global TapRooT® Summit, June 14-18, 2021, in Knoxville, Tennessee, is the best setting to help you develop your roadmap to success. Register your team to attend and meet global industry leaders and network with instructors and professionals.

Look through the 2021 Global TapRooT® Summit schedule to browse the tracks and then . . .

- Peruse and take advantage of the Pre-Summit Courses (June 14-15).

- Read Summit FAQ.

- Save money! Register 3 or more attendees simultaneously for a discount. Also, save when you register for the 3-day Summit plus a 2-day Pre-Summit course.