What Does It Cost To Wait?

Is Waiting Free?

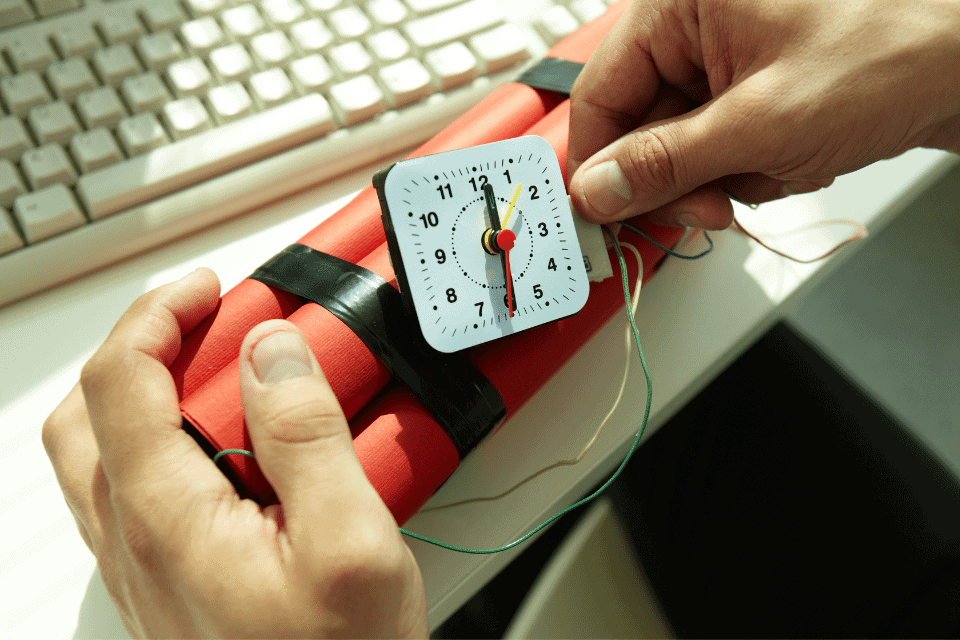

The COVID pandemic has caused many people to wait to implement plans to improve. The question we will address today is:

What does it cost to wait?

Potential Costs

Let’s do some brainstorming as to potential costs that could occur when you DON’T implement your improvement plans…

- A major accident occurs because you didn’t improve safety or process safety. The cost? Could someone die? A major accident could cost your company millions.

- Equipment failures continue because you didn’t implement an equipment reliability improvement initiative. The cost? Potentially hundreds of thousands of dollars due to plant downtime.

- Quality issues cause customer complaints or regulatory issues. The cost? Hard to evaluate. What could the regulatory fine be? What would losing your best customer cost?

That’s just three quick examples. What other examples can you imagine?

What Improvements Are You Delaying?

Let’s make a list of the improvement initiative that you might be delaying?

- Attending a conference to get new ideas for your improvement efforts?

- Training for you or your people to learn the skills needed to successfully improve performance?

- Revising your improvement initiative to make it more effective?

- Getting increased management support for improvement initiatives?

- Broadening the scope of your improvement plans to get more benefits from your improvement technology?

Now, revisit what the potential costs of each of these delays might be.

Get Going!

I believe when you evaluate your delays and the costs that each delay might incur, you will probably see that you need to get your improvement program going!

Yes, COVID has made it more difficult to make improvement happen. But you need to redouble your efforts and DO IT NOW!

Ideas for Improvement Initiatives

Here are three ideas to help you improve your improvement initiatives.

- Is it time to improve your root cause analysis? You could contact us to schedule an on-site course, a public course, or the new VIRTUAL TapRooT® Root Cause Analysis Training. Or you could attend a webinar on a particular topic to boost your knowledge.

- Do you need new ideas to improve performance and make or keep your company an industry leader? Then you should start planning to attend the 2021 Global TapRooT® Summit. This once a year event is an opportunity that you should take advantage of and it is coming up in June. And if you really want to make improvement happen, consider bringing a team to the Summit. Get more information about bringing a team HERE.

- Contact us for a management briefing and to develop a roadmap to success. For more information, CLICK HERE.