What is Root Cause Analysis?

What is Root Cause Analysis?

The Answer Starts with a Definition.

What is root cause analysis? How can you find root causes? Let’s start with the definition of a root cause…

ROOT CAUSE

“The most basic cause (or causes)

that can reasonably be identified,

that management has control to fix and,

when fixed, will prevent (or significantly reduce

the likelihood of) the problem’s recurrence.”

The definition above is the original definition we used in the early 1990s. But in 2006, we published a new, improved definition of a root cause…

“ROOT CAUSE

A Root Cause is the absence of a

best practice or the failure to apply knowledge

that would have prevented the problem.”

Why did we change the definition and how is the new definition of a root cause an improvement? To read more about these root cause definitions, CLICK HERE.

What is root cause analysis?

Using the second definition, the answer to the question: “What is root cause analysis?” is:

WHAT IS ROOT CAUSE ANALYSIS?

“The systematic process of finding the

missing best practices or knowledge

needed to prevent a problem.”

That is the simple answer to the question: “What is root cause analysis?”

But effective root cause analysis is NOT simple. Why? The devil is in the details.

How Simple Can Root Cause Analysis Be?

Many say that you can use a simple root cause analysis technique, like 5-Whys, to perform a root cause analysis. Who says that? The people who wrote these articles:

5 Whys: The Ultimate Root Cause Analysis Tool

The 5 Whys Process We Use to Understand the Root of Any Problem

Determine the Root Cause: 5 WHYS

We don’t agree. In several articles, we have explained that 5-Whys is NOT an effective root cause analysis tool. If you want to be convinced of the inadequacies of 5-Whys, read this post:

Comparing 5-Why Results with

TapRooT® Root Cause Analysis Results

An even simpler explanation of why you should not use 5-Whys for root cause analysis is that it doesn’t lead you beyond your current knowledge. As Albert Einstien said…

You don’t want to argue with Einstien.

Instead, review the fundamentals of root cause analysis and see what you need to do to find real root causes. Read the article at this link:

https://www.taproot.com/about/root-cause-analysis-fundamentals/

A Simple (but not too simple) Root Cause Analysis Process

To have a simple but effective root cause analysis, investigators need guidance. Guidance to troubleshoot equipment problems and guidance to analyze human errors. We’ve written about guided root cause analysis before (CLICK HERE).

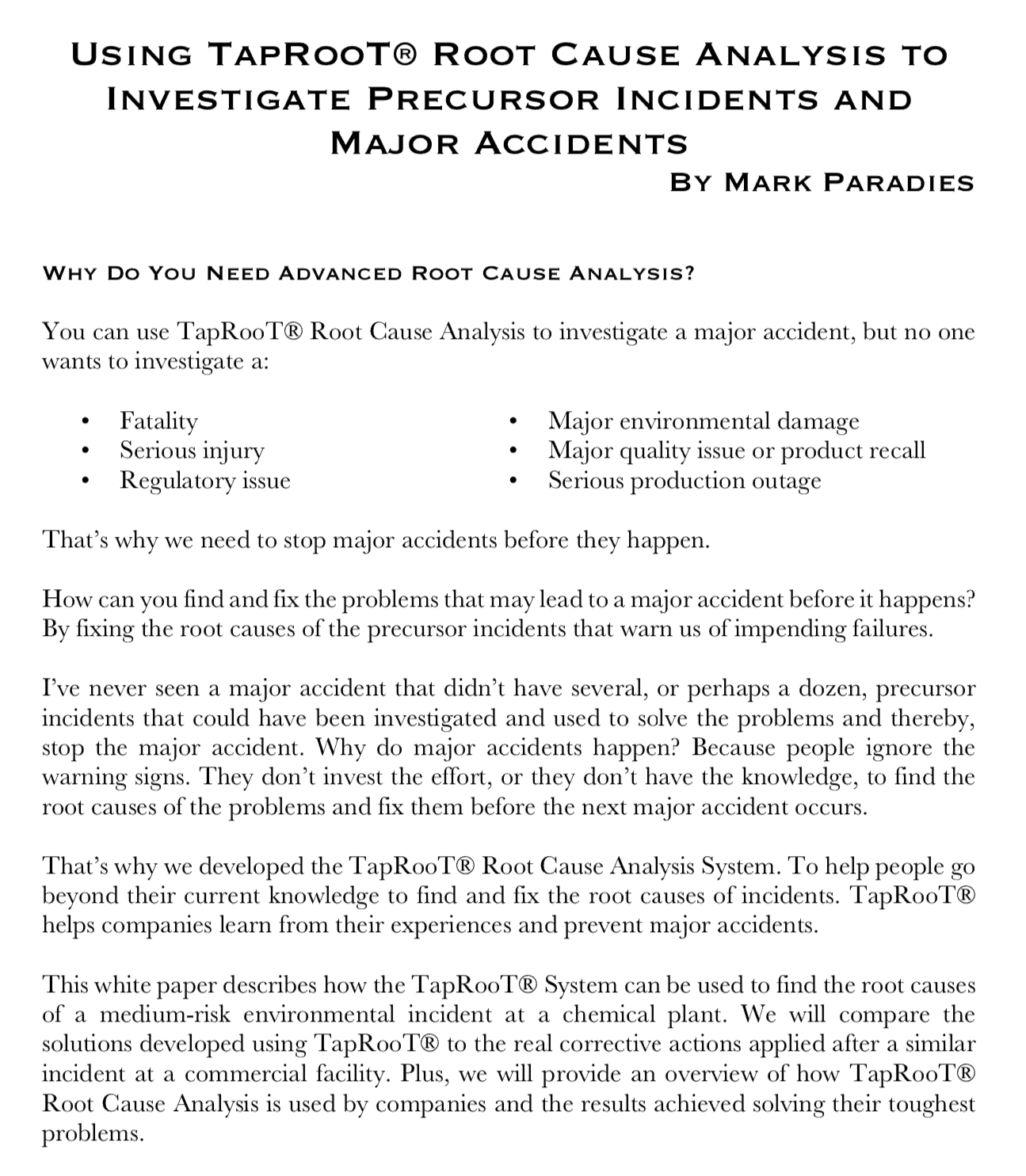

We spent more than 30 years developing and improving a root cause analysis system called TapRooT® to provide effective guidance for the analysis of human performance and equipment reliability problems. That hard work has the creation of a root cause analysis tool that is recognized around the world for its effectiveness.

Why does TapRooT® Root Cause Analysis work so well? Because it meets all the requirements of the fundamentals of root cause analysis. It is a combination of two processes and the best practices to guide your investigation and root cause analysis.

Let’s start with the two processes – a simple process for simple incident root cause analysis (precursor incidents) and a more complete process for major investigation root cause analysis (accidents with high consequences).

One important part of this simple root cause analysis process is that it uses all the essential TapRooT® Tools and provides investigators with a way to save time and effort if they find, early on, that there is nothing more to be learned from the further investigation. Once they have the initial information on their SnapCharT®, they can STOP the investigation (if they decide there really isn’t anything important to learn).

Root Cause Analysis for Major Accidents

The process for major investigation root cause analysis looks like this…

This process has all the TapRooT® Essential Tools plus the Optional TapRooT® Root Cause Analysis Techniques and looks for Generic Causes.

TapRooT® Root Cause Analysis Tools

What are the essential TapRooT® Root Cause Analysis Tools?

- The SnapCharT® Diagram

- The Equifactor® Troubleshooting Tables

- The Root Cause Tree® Diagram

- The Corrective Action Helper® Guide/Module

The SnapCharT® helps you collect and organize information to help you understand what happened.

The Equifactor® Troubleshooting Tools help you understand what happened to cause equipment failures.

The Root Cause Tree® Diagram guides you to the root causes of human performance and equipment reliability issues.

The Corrective Action Helper® Guide/Module helps you develop effective fixes based on vest practices from around the world.

Of course, that’s just the start of what makes the TapRooT® Root Cause Analysis System an international best practice.

For a short white paper that describes the TapRooT® Root Cause Analysis Tools, see:

CLICK HERE to download the entire paper.

Once You Understand “What is Root Cause Analysis?” … It is Time To Learn More!

For a more complete description of how to use the TapRooT® Root Cause Analysis System to investigate precursor incidents, read the book, Using the Essential TapRooT® Techniques to Investigate Low-to-Medium Risk Incidents.

For a complete description of using TapRooT® Root Cause Analysis to investigate major accidents, read the book, Using TapRooT® Root Cause Analysis for Major Investigations.

And to learn how to investigate both precursor incidents and major accidents, attend our 5-Day TapRooT® Advanced Root Cause Analysis Team Leader Training. See the dates and locations of upcoming public 5-Day Courses being held around the world at:

https://store.taproot.com/5-day

Do you want to hold an advanced root cause analysis course at your site? Contact us by CLICKING HERE. Then have your whole staff learn advanced root cause analysis.

If you have questions about TapRooT® Root Cause Analysis and how it can help your company improve by finding and fixing the root causes of problems, call us at 865-539-2139. We’ll be glad to set up an executive briefing and, if you are interested, develop a roadmap to successfully implement advanced root cause analysis – TapRooT® Root Cause Analysis.