Makeshift Work Stage Results in Serious Injuries

Two crewmen sustained serious injuries in the process of working aloft.

What serious incident caused these crewmen to become injured? On January 11, 2018, bulk carrier Berge Daisetsu was berthed in Portland, Victoria. A team of six crew members was cleaning and painting the cargo hold under the supervision of the chief mate. While the vessel did not have portable scaffolding equipment or approved suspended access platforms for this task, the master discussed other options with the chief mate and bosun for how the upper sections of the hold could be tended to.

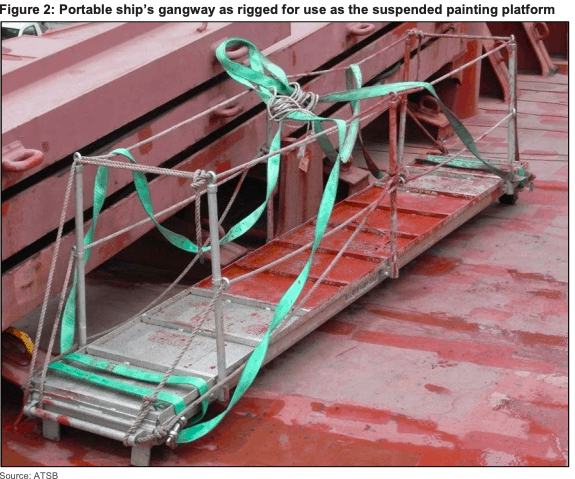

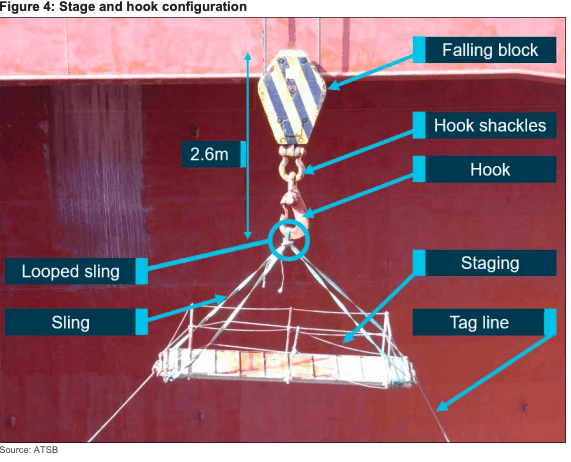

The decision was made to jury-rig a portable gangway into a work stage which could then be suspended from the cargo crane hook via slings. The ship’s crew members had several discussions, made plans, and completed a risk assessment in accordance with the safety management system requirements. However, the equipment and machinery use was contrary to company policy and procedures.

As two crew members worked aloft on the platform suspended from the cargo crane, the crane’s block caught on the coaming and suddenly came free, sending an unexpected heavy shock into the platform. The two crew members were knocked over by the force of the sudden movement and landed heavily on their knees and lower body, causing serious injury.

Lessons learned from serious injuries

The ATSB (Australian Transport Safety Bureau) investigation found that the equipment and machinery were not suitable for the task, making hazard identification difficult, and exposed the workers to increased risk.

“This accident illustrates the consequence of deviating from accepted safety management procedures and industry best practice,” said ATSB Director Transport Safety Stuart Macleod.

“The use of machinery and equipment contrary to its intended purpose makes hazard identification difficult and exposes those directly involved to significantly increased risk.”

The investigation also found that the fall arrest equipment used was incorrectly attached to the workers on the suspended platform. Consequently, had either of them fallen from the platform, the equipment would not have worked correctly, resulting in serious or fatal injuries.

Revised practices to avoid further serious injuries

As a result of this serious incident, Berge Bulk Maritime has completed the supply of approved working aloft equipment to its geared bulk carriers and is progressing modification of vessel cranes for personnel lifting. Specific working aloft and bulk carrier safety training has been conducted and made mandatory for crewmembers every two years.

In addition, a fleet-wide assessment of safety maturity is progressing.

Source: ATSB; read the report: Serious injuries onboard Berge Daisetsu, Portland, Victoria on 11 January 2018.

Founded in 1988, the TapRooT® Root Cause Analysis System solves hurdles every investigator faces

TapRooT® Root Cause Analysis Training System takes an investigator beyond his or her knowledge to think outside the box. Backed with extensive research in human performance, incident investigation, and root cause analysis, TapRooT® is a global leader in improved investigation effectiveness and productivity, stopping finger-pointing and blame, improving equipment reliability, and fixing operating problems.

System Improvements, the creator of the TapRooT® System, has a team of investigators and instructors with years of extensive training ready to offer assistance worldwide.

TapRooT® Root Cause Analysis Training courses are taught all over the world

If you are interested in learning how to stop repeat incidents, find a 2-Day or 5-Day course; or view the complete selection of TapRooT® courses. We are available to train you and your staff on-site at your workplace; Contact us to discuss your needs. You may also call us at 865.539.2139 to discuss any questions you may have.

Keep in touch to improve your problem-solving skills

We’re continually training, helping you improve your professional root cause analysis skills. Stay current with your TapRooT® Root Cause Analysis skills and training through:

- Following our blog;

- Free newsletters;

- Tuning in to TapRooT® TV Video Sessions or our podcasts;

- Connecting with us on Facebook, Twitter, Instagram, Pinterest, LinkedIn, and YouTube;

- And our annual Global TapRooT® Summit.