Rail Incident Highlights Importance of the Comprehension of Suitable Procedures When Developing Safe Working Rules

Could a mistaken belief by a fatigued relief signaler have caused a lapse in suitable procedures in diverting trains?

A relief signaler was working on two signal panels at once when he didn’t employ suitable procedures and instead routed a train through a protected worksite; the worker was possibly experiencing the effects of cumulative fatigue as well as being under a high workload, a transport safety investigation report details.

On the evening of October 15, 2019, two Sydney Trains workers and a Protection Officer (PO) were conducting track work between Parramatta and Westmead stations, in Sydney’s west.

Absolute Signal Blocking (ASB) was being used to protect the worksite, with the PO arranging suitable procedures with the signaler for a pair of signals to be set to stop to prevent trains from entering the section.

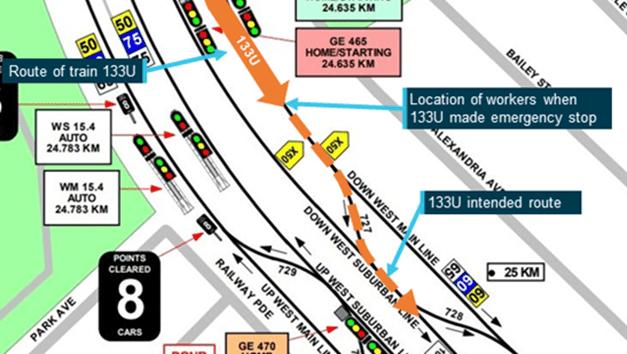

However, the signaler directed an approaching passenger train to enter the section by removing the blocking for the two signals, with the intention of routing the train through a set of points to take it onto the adjacent track, to go around the track workers.

After passing the signals, the train driver saw the workers on the track in front of them, sounded the train whistle, and applied the emergency brakes.

The workers were able to vacate the track and danger zone, as the train came to a stop near where the workers had been.

An investigation into the incident was undertaken by the Office of Transport Safety Investigations (OTSI), which conducts rail safety investigations in NSW on behalf of the Australian Transport Safety Bureau.

“The investigation found the relief signaler at Granville signal box had mistakenly believed the workers were further away from the location that was provided in the agreed arrangements for Absolute Signal Blocking,” OTSI Chief Investigator Dr Natalie Pelham said.

“This mistaken belief led to the signal protection for the worksite being removed to allow a train to go around the workers using an alternative route.”

The signaler and the PO had discussed the need to divert trains around the worksite, but neither had correctly comprehended the implications of doing this.

“The relief signaler was possibly experiencing the effects of cumulative fatigue due to rostering issues, as well as experiencing a high workload,” Dr Pelham said.

The rostered signaler at the Granville signal panel was absent from the workstation at the time of the incident, and the relief signaler was operating both the Granville and Westmead signal panels.

“Sydney Trains did not provide suitable management arrangements for supervision at Granville signal box to ensure there was adequate coverage on both signalling panels,” Dr Pelham said.

“Signalers are safety critical workers who perform work which is vital to the safe performance of the rail network.

“These workers require supervision and should be subject to suitable management arrangements to ensure compliance to relevant work instructions and requirements.”

The relevant Network Rules and Procedures for ASB had very little direction and guidance to workers about how to manage the risk of clearing a protecting signal for an alternative route in order to run a train, the investigation notes.

“Railway safeworking rules are in place to achieve safe rail operations and should be developed so that the desired outcomes are supported by suitable procedures,” Dr Pelham noted.

Sydney Trains temporarily prohibited the practice of signalers being permitted to clear any signals used for ASB protection in order to run trains via an alternative route.

Subsequent changes to the ASB rule and procedure were implemented in December 2020 to prohibit the clearing of the signal immediately protecting a worksite in order to run a train via an alternative route.

The investigation also found there were inconsistencies with Sydney Trains’ application of their fatigue management system, in particular, the use of a bio-mathematical model to predict individual fatigue risk.

Key points

- A relief signaler who was working on two signal panels at once directed a train through a protected section of track;

- Operator’s relevant rule and procedure for Absolute Signal Blocking did not provide sufficient description for using protecting signals for an alternative route around a protected section of track;

- Signaler’s recent work schedule failed to meet operator’s fatigue management principles.

Read the full ATSB report: “RO-2019-018: Near hit with workers on track using Absolute Signal Blocking, Westmead, New South Wales, on 15 October 2019.”

Circumstances can crop up anywhere at any time if proper and safe sequence and procedures are not planned and followed. We encourage you to learn and use the TapRooT® System to find and fix problems.

TapRooT® has a team of investigators and instructors with years of extensive training ready to offer assistance worldwide. We also offer ongoing support to our clients through free newsletters and root cause tip videos, the root cause analysis blog, and our annual Global TapRooT® Summit.

Register for one of our courses. We offer a basic 2-day course and an advanced 5-day course. Contact us or call 865.539.2139 about having a course at your site or for further root cause analysis opportunities. We’re here to find solutions for you.

Contact us to discuss training your employees on-site. You may also call us at 865.539.2139 to speak to an instructor, schedule an executive briefing, or book on-site training for your team.