When To Perform a Root Cause Analysis? And How?

When to Perform a Root Cause Analysis?

How to Perform a Root Cause Analysis?

Does every mistake deserve a root cause analysis? NO. So, when should you perform a root cause analysis? That’s the first question we will answer below.

When you perform a root cause analysis, how much effort should you expend? Are there different levels of effort that you can expend and still get acceptable results when you are analyzing minor incidents compared to major investigations? These two questions will also be addressed below.

If you are interested in when to perform a root cause analysis and how … read on!

When to Perform a Root Cause Analysis?

Resources … When you investigate incidents, you are expending resources:

- Your time

- Your team’s time (if it is a major investigation)

- Management’s time to review the results

- The time and resources to implement fixes

Let’s face it, there are some incidents that don’t warrant investigation. For the purpose of this article, we will call them “paper cuts.”

Paper cuts are not likely to cause a more serious injury.

A paper cut won’t cause a decapitation or the loss of a limb.

Even an infection is unlikely.

However, some minor injuries could be precursors of a more serious injury. These PRECURSOR INCIDENTS are worth investigating.

What is a precursor incident? Have a look at the incident in the video below.

No one was injured … BUT … Could someone have been seriously injured?

I would say that someone certainly could have been severely injured. This incident was certainly a precursor incident and deserves a root cause analysis.

How Do You Get Consistency in Identifying Precursor Incidents?

Two ways…

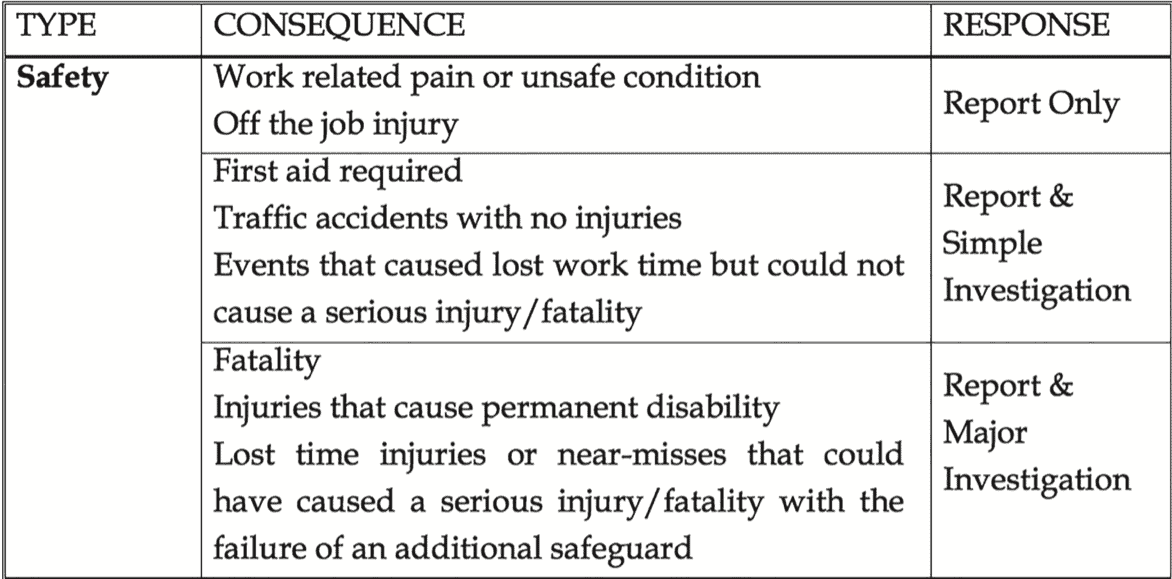

First, in your incident investigation policy, you define what gets investigated. For industrial safety incidents, it could look something like this…

The above table is from Book 2, TapRooT® Root Cause Analysis Implementation by Mark Paradies and Linda Unger, copyright © 2017 and is used by permission. For a complete set of suggestions for your policy including :

- Industrial Safety

- Process Safety

- Environmental

- Quality

- Production and Schedule

See pages 64-65 of Book 2.

Second, we became aware of the work of Dr. Matthew Hallowell. He led a group of industry professionals that came up with the “Energy Wheel.”

One of the applications of the wheel is to identify incidents where Safeguards (Gravity – Motion – Mechanical – etc. … Safeguards) failed and the energy present was enough to more than likely cause a serious injury or fatality. Thus, an incident where a person falling down a single step would not be enough to more than likely cause a fatality. But an incident where someone fell off a ladder 12 feet high would be enough energy to more than likely cause a serious injury or fatality. Dr. Hallowell teaches about performing these calculations. If you would like to learn more about performing accurate calculations of what is a precursor incident based on Dr. Hallowell’s research, see:

https://www.safetyfunction.com/energy-based-hazard-recognition

How to Perform a Root Cause Analysis

After you decided to perform:

- No Investigation

- A Simple Investigation

- A Major Investigation

Based on the actual or potential risk of the incident, you next have to decide HOW you will perform the investigation. In developing the most recent series of TapRooT® Books and Training, we designed two different investigation processes. One for simple incidents (low to moderate risk) and one for major investigations.

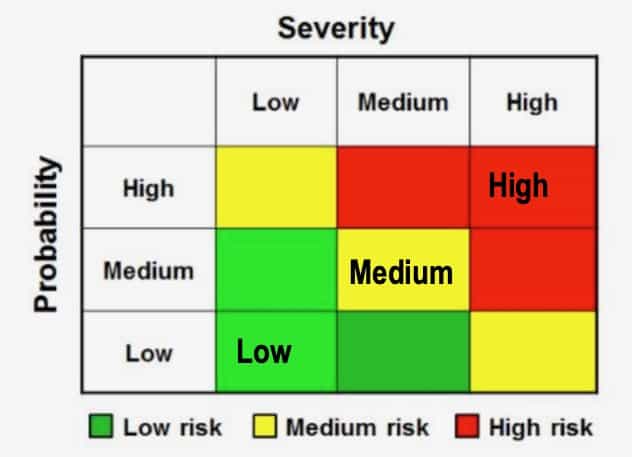

When deciding if an incident deserves a major investigation, you need to decide the probability and severity of potential future incidents. Those in the red zone below are “high risk” incidents and deserve a major investigation.

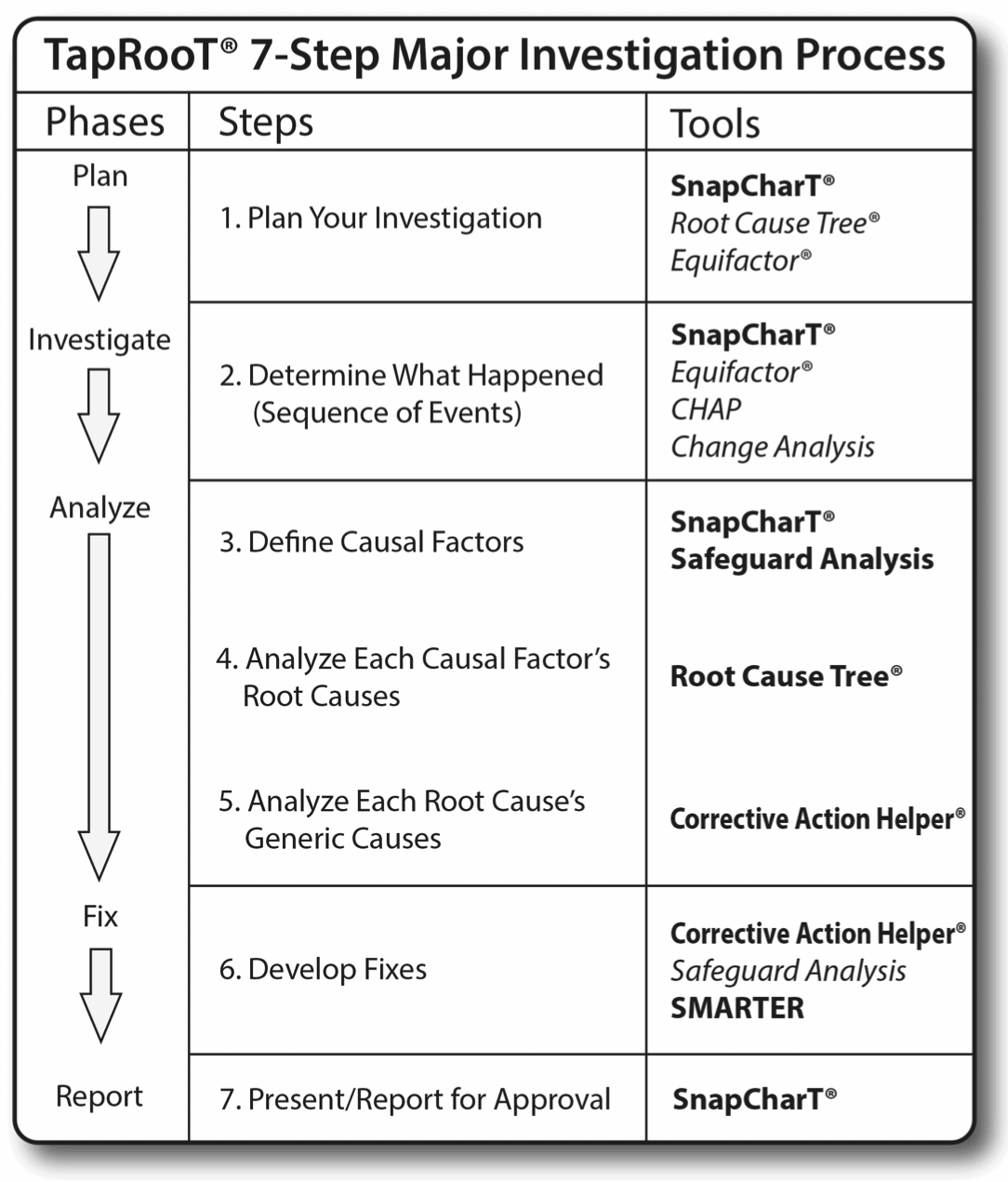

How do you perform a major investigation? The process (shown below) is detailed in TapRooT® Book 4, Using TapRooT® Root Cause Analysis for Major Investigations.

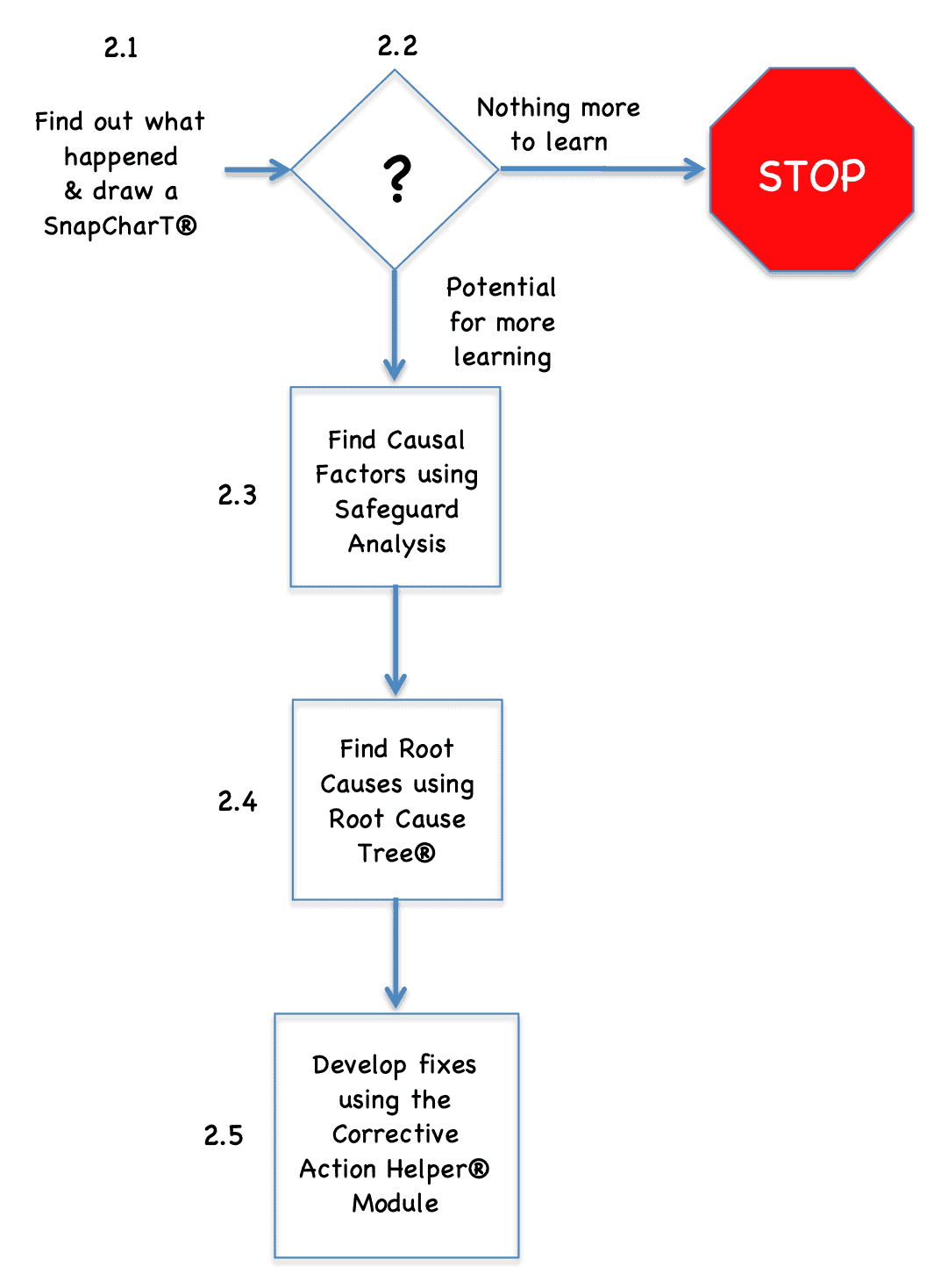

What about an investigation of a low-to-medium risk incident? If the table indicates that you should perform an investigation, you would apply the simple investigation process (shown below) that is detailed in TapRooT® Book 3, Using the Essential TapRooT® Techniques to Investigate Low-to-Medium Risk Incidents.

Both of these investigation processes are copyrighted and are used here by permission.

Note that there is a decision step in the simple investigation process shown above. After you develop your initial SnapCharT® of what happened, you can decide that there is nothing more to learn and stop the investigation without identifying the Causal Factors or the Causal Factors’ root causes.

Stopping an investigation early in the process when you decide that the lessons learned won’t be that important can save considerable investigative effort.

Learn How To Perform the Right Root Cause Analysis

We mentioned the books that detail how to use root cause analysis techniques for simple and major investigations but there are also courses to teach you the techniques and processes.

First, there is the 5-Day TapRooT® Advanced Root Cause Analysis Team Leader Training. It teaches how to use either the simple or the major investigation processes and the techniques needed yo investigate:

- simple human errors

- equipment failures

- major accidents

If you want to learn all the TapRooT® Tools for these investigations, the 5-Day Course is the course to attend.

Next is the 2-Day TapRooT® Root Cause Analysis Training for those that investigate low-to-moderate risk incidents. We call it the essentials course because, in just two days, it teaches the techniques that are essential to perform a TapRooT® Root Cause Analysis.

Finally, there is the 2-Day Equifactor® Equipment Troubleshooting and TapRooT® Root Cause Analysis Training. This course was developed for people who mainly focus on equipment reliability issues.

When and where can you attend one of these courses? See our store at this link:

https://store.taproot.com/all-locations

Don’t wait. These public courses have very limited seats to comply with our COVID protection guidelines. Sign up early to make sure you get a seat!

Mark, I am not sure I agree with the example of an Incident Investigation Policy chart listed in the When to Perform Root Cause Analysis. The answer is not a simple one. I believe we need to ask three questions: “What if”?, “What is the Potential?” and “likelihood of occurrence?” Of course using the Probability and Severity chart as a guide. I remember a case I investigated years ago. where a maintenance person was changing a Florescent lamp in a restroom.

The lamp had been changed many times in the past without an incident. However maintenance had reported several near misses in the past dealing with lamp access. Seems the lamp was over the stall divider making access difficult. So maintenance generally climbed up on the back of the toilet with one foot on the stall divider. One of the things we found out was LOTO was not practices since it was perceived to be insignificant voltage or risk associated with changing the lamp. In this case, the maintenance man receive a low-voltage shock which startled him causing him to fall striking his neck on the stall divider on the way down. This simple task ended in a fatality!

Our Root Cause Analysis clearly indicated that there was potential for serious injury, no JSA for task, or follow-up on previously reported concerns.

Two points.

First, the policy chart says a major investigation is required for lost time injuries or near-missed that could have caused a serious injury or fatality.

Second, the height involved is probably sufficient to be counted as an energy that could cause serious energy when using the Energy Wheel to evaluate the potential for a serious injury.

Thus, I think your example would be covered by the policy/Energy Wheel and would require a major investigation.

However, I think the energy involved is on the low side and the accident was rather unusual (striking his neck on the divider after being shocked). So, it may be possible that they would not have seen the Hazard as significant. The multiple near-miss reports might have caught the problem in trending.

Finally, it would be easy to add words to the simple investigation category that could cover this case. The words that describe the use of the investigation matrix suggest that you can customize it based on your risk tollerance.

Excellent approach to optimise resource vs requirement