ETOPS Incidents: Spectrum of Challenges

If you have flown on or operated an air carrier flight that boasted an oceanic crossing, the flight was likely conducted using ETOPS criteria.

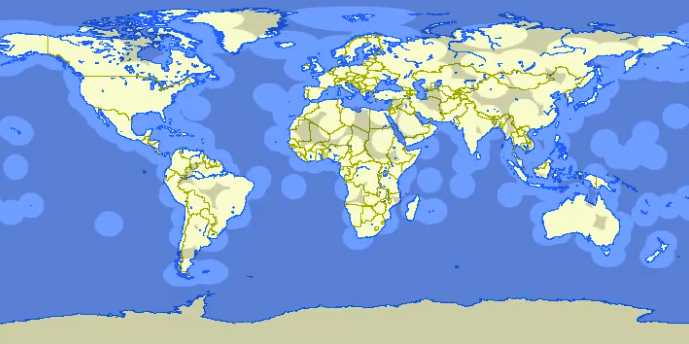

ETOPS procedures are mandated for turbine-powered aircraft with two engines when a flight is conducted farther than 60 minutes flying time from an adequate airport at an approved one-engine inoperative cruise speed under standard conditions in still air. The flying time increases to 180 minutes for aircraft with more than two engines. Many subtle, but important flight safety concepts are expressed in ETOPS operations.

Changing conditions, contingencies based on flight progress, various diversionary situations, and ETOPS regulations all contribute to complexity. ETOPS procedures penetrate many aspects of an ETOPS flight. They require precise execution at multiple levels and junctures. Advisory Circular 120-42B provides an excellent description and information on ETOPS operations.

We’re going to be looking at reported ETOPS incidents that reveal a spectrum of ETOPS challenges, the practicality of common sense in the responses, and a perception of the effort required for prevention or effective mitigation.

ETOPS and Other Distractions

Difficulties combining ETOPS requirements with changes to closed airspace effectively distracted this Dispatcher into overlooking other important requirements for flight.

Due to numerous changes with airspace closures and restrictions due, in turn, to COVID cleaning at ARTCCs, I was so concerned with keeping this flight out of ETOPS areas while still avoiding airspace closures, that I totally missed the requirement for HF communication when the flight dipped into ZZZ (oceanic) airspace. It may be [good to] have an alert reminding us to check for HF requirements when routing through specific Flight Information Regions.

Planning for ETOPS

A Dispatcher reported an ETOPS planning error that was discovered in flight by the crew. Fortunately, fuel margins and flight safety were not ultimately compromised.

I took over this flight from another shift. Normally this flight is scheduled to operate from ZZZZ to ZZZ, but due to ZZZ weather, it was rescheduled to arrive at ZZZ1. The flight was sent with a re-dispatch and ETOPS alternates of Keflavik and St. Johns and no destination alternate for ZZZ1. While enroute and well past the ETOPS Entry Point (EEP), the crew sent an ACARS message, “What airport is defining ETOPS exit?” I checked the flight plan and noticed that the ETOPS Exit Point (EXP) was [defined by] ZZZ1. The EEP airport was correctly identified as Shannon, and the Equal Time Point (ETP) location seemed accurate when looking at the route. I tried to figure out the reason for this, including creating dummy flight plans . . . and was unable to get a proper EXP. I advised the crew that the correct EXP defining airport was Goose Bay (using range rings to define) and that while the EXP on the release was not correct, the critical fuel scenario based on the ETP between Keflavik and St. Johns seemed accurate. I asked a few peers to review this to make sure I wasn’t missing something, and they all agreed. Another Dispatcher found a similar issue on a similar routing . . . [from] ZZZZ to ZZZ1. I advised the Dispatcher on duty, and he contacted [management] immediately.

Logbook, Legality, and ETOPS

A Captain described an appearance of compliance, while a Lead Aviation Maintenance Technician (AMT) revealed details of an aircraft departing without a completed ETOPS pre-departure check (PDC). Remedies are prescribed. From the Captain’s report:

The Chief Pilot notified me that we departed without an ETOPS pre-departure check and with an open aircraft maintenance log (AML) write-up for the same issue.

The logbook had all the ETOPS pre-departure work cards for the mechanics in it that made it appear that the check was completed, and that caused confusion. The logbook was on the airplane in the normal location. When there is an open write-up, they could remove the logbook from the storage bin and return it when the write-up has a corrective action.

From the Lead Technician’s report:

The aircraft . . . left our station . . . for a scheduled . . . departure with an open logbook entry for the ETOPS PDC. Steps 1 through 8 [were] completed, but the final steps [were] not accomplished.

The aircraft was towed to the gate . . . and was never assigned to anyone to accomplish the final ETOPS steps of the PDC. We have been splitting workload between Terminal Y and Terminal X Maintenance personnel. Terminal Y AMTs had been accomplishing all . . . ETOPS PDCs, since most of the Terminal X AMTs were out on pandemic leave. Terminal Y AMTs have primarily covered four gates and the . . . ETOPS [checks]. Terminal Y personnel did not have a Crew Chief yesterday and assumed that Terminal X AMTs were accomplishing trip ABC’s ETOPS [PDC], as it was leaving from [a Terminal X] gate. As . . . Supervisor, I was consumed with problems on [two other aircraft] . . . and did not follow up on trip ABC’s ETOPS [PDC] prior to shift change. Trip ABC . . . departed on the evening shift. I did not give . . . enough detail . . . to the oncoming crew about [aircraft] status.

Going forward, Terminal X AMTs will be accomplishing all of the ETOPS PDCs leaving from Terminal X. We will be assigning AMTs to meet and greet every arriving aircraft upon arrival at the gate, regardless of inbound flight or a taxi/tow up from remote or a hangar, to debrief the flight crew and get eyes on the logbook. As the Supervisor on shift, I will be backstopping, double checking, and verifying compliance with this policy. I will be briefing the crew daily to make sure these expectations are clear and understood.

We will be giving a detailed written and verbal turn-over to…oncoming crew chiefs and management . . . about the status of work that is in progress and yet to be accomplished. We will be giving parking locations and taxi/tow up times for the ETOPS flights that are departing on the evening shift.

ETOPS Qualification

An AMT highlighted a problem where non-ETOPS qualified management personnel determined final sign-off status and reported official progress on ETOPS checks.

The shift manager advised us in the ETOPS office today that management could no longer stamp the “Accomplishment Reporting” of the last page of the ETOPS check. This is due to most members of management not being fleet ETOPS qualified. Since manning the ETOPS office for 7 months, it has been customary that management stamps the box in question and accomplishes the associated transaction on [the maintenance computer system]. Now I’m discovering management was not qualified to stamp the box.

Fuel, Pumps, and ETOPS

A B757 First Officer chronicled an aircraft malfunction that developed into a fuel crisis and required action. The situation mimics the classic hypothesis of the ETOPS question, and the crew’s solution precipitated clarity from common sense.

In the original paperwork, the deferred-in-place log mentioned that the aircraft was previously written up for a “CTR R FUEL PUMP” EICAS [caution] message and center right fuel pump low output pressure [with the associated] “LOW PRESS” light [on] and fuel in the center tank.

The preflight went normally, and the center fuel pumps checked good. After a normal engine start, we started taxiing. During the taxi, the Captain noticed the “CTR R FUEL PUMP” EICAS message. . . We returned to the gate. After about an hour and a half, Maintenance changed a part, and the pump appeared to work normally.

While at the gate we looked at the MEL, which [included the] Center Tank Fuel Pumps Special Procedure, Note A: “One may be inoperative with center tank fueled provided: A. Fuel quantity in main tanks is adequate to reach a suitable airport if remaining center tank pump fails at any time.”

After accomplishing all of our checks, we departed. . . . On the climb, passing around 16,000 feet, we noticed the center fuel pump EICAS [message] and associated “LOW PRESS” light on the right center fuel pump switch. We accomplished the QRH Checklist, which directs switching the affected pump to off, and switching on the crossfeeds. There is no mention in the QRH about ETOPS considerations. While I was flying and talking with ATC, the Captain ended up talking with Dispatch, [Maintenance Control], and the [Chief Pilot] over HF. We also looked at our ETOPS fuel required at the ETP, which was 29,597 pounds. At that point, in our wing tanks, we had a total of about 27,200 pounds (about 14,400 in the left and 12,800 in the right), meaning that if the remaining center tank failed around the ETP, there would not be enough fuel in the main tanks to reach a suitable airport. The Captain and I discussed [the situation], and agreed that continuing toward the ETP would be unnecessarily risky. While the Captain discussed options with Dispatch, [Maintenance Control], and the [Chief Pilot] on HF and had difficulty hearing them, I coordinated with . . . Center to stay in their airspace before a final determination was made. Eventually, it was agreed by all parties to return to [the origination airport]. At our . . . weight, we would land about 18,000 pounds heavy. Dispatch approved the overweight landing and asked us to [advise ATC], which we did.

With the construction on . . . [Runway] XXL reducing its usable runway length to 9,100 feet, we requested and were approved to land on . . . [Runway] XXR, a 12,000-foot runway. I did the visual landing . . . with an RNAV backup. There is no ILS [for Runway] XXR. The landing was uneventful, and the [event] was terminated. The brakes heated up to a level 4 at most. We ended up taking another aircraft and departing . . . two and a half hours later.

Source: CallBack 501, October 2021, “Extended Operations (ETOPS and Polar Operations),” NASA Aviation Safety Reporting System.

Circumstances can crop up anywhere at any time if proper and safe sequence and procedures are not planned and followed. We encourage you to learn and use the TapRooT® System to find and fix problems.

TapRooT® has a team of investigators and instructors with years of extensive training ready to offer assistance worldwide. We also offer ongoing support to our clients through free newsletters and root cause tip videos, the root cause analysis blog, and our annual Global TapRooT® Summit.

Register for one of our TapRooT® courses. We offer a basic 2-day course and an advanced 5-day course. Contact us or call 865.539.2139 about having a course at your site or for further root cause analysis opportunities. We’re here to find solutions for you.

Contact us to discuss training your employees on-site. You may also call us at 865.539.2139 to speak to an instructor, schedule an executive briefing, or book on-site training for your team.